Welcome to 2016!

What follows is a summary of our activities for the fourth quarter of 2015. I think you will agree that it has been a very good year for us and that we are starting strong for this new year. As always, we owe a lot of our success to our strong partnerships with the City of Calgary, the Bomber Command Museum of Canada, Historic Aviation Services, the Calgary Foundation, the Province of Alberta and of course you, without whom none of this would have been possible. Enjoy our mutual success.

Volunteer Hours

Board members of the Mosquito Society worked a total of 248 hours during the fourth quarter of 2015. These are the hours invested in running the organization that then allows the restoration work on the airplanes to take place. This includes tasks such as monthly board meetings, report writing, banking, accounting, fundraising, communications, website updates, presentations, etc.

Additionally, members of the society worked 1012 hours on the Mosquito and 492.75 hours on the Hurricane engine over the same period on 25 separate dates in Calgary and in Nanton.

Volunteer hours for this quarter total 1752.75. This is up 204 hours over the previous quarter and is 642 hours, or 58%, more than for the same quarter last year, representing an all time high number of volunteer hours since taking possession of the aircraft in August 2012.

Fundraising

On November 9 the Alberta Gaming and Liquor Commission deposited funds in the amount of $73,100.06 from our August 27/28 casino. On December 16th we received the final payment of $17,000 against our $65,000 grant for video production from the Calgary Foundation.

Hurricane

Historic Aviation Services' focus during the past quarter continues on the restoration of the airplane's center section. We conducted our onsite inspection for this quarter on December 18th.

Airframe: Historic Aviation Services

- Finished cleaning fuel tanks, inspected and determined condition. (Note: Relative to the goals of the project and in discussion with the CMS, it was decided to repair the fuselage fuel tank in order to allow ground running of the engine. The port and starboard centre section fuel tanks will be stabilized and restored cosmetically but will not be useable).

- Central, centre section gear bay panels were stripped, cleaned, inspected, repaired as required, primed and doped with silver butyrate. New landing gear inspection windows made up and installed, new leather closing strips made up and installed using originals for patterns.

- Central, centre section gear bay panels fitted and installed in place.

- Rear centre section gear bay panel stripped, cleaned, inspected, repaired as required, primed, doped with silver butyrate and installed in place.

- Made up centre section stand-off brackets and clamps (originals missing) primed, doped with silver butyrate and installed in place.

- Made up firewall phenolic spacers and attaching clamps (originals missing) primed, doped with silver butyrate and installed in place.

- Centre section flap bay panels stripped, cleaned, inspected, repaired as required, primed, doped with silver butyrate and installed in place.

- Lower centre section radiator enclosure panels stripped, cleaned, inspected, repaired as required, primed, doped with silver butyrate and installed in place.

- Lower, inner centre section panels inspected and repaired as required. Port and starboard vertical sections made up (originals missing). All primed, doped with silver butyrate and installed in place.

- Prepared and painted radiator. Trial fitted radiator and associated belly enclosure panels to aircraft.

One of the two center section fuel tanks. Self sealing outer layer being stripped and restored. The two center section tanks will not be serviceable as corrosion has perforated the metal in dozens of places.

Underside of the center section showing gear bay panels, fuel tank (red) and radiator (less oil cooler). Note also the two new landing gear inspection windows through which the pilot could look down to see if the wheels were securely extended or retracted.

Looking as much like a steel girder bridge as an airplane, the structural heart of the Hurricane is its robust center section, seen here coming together with flap bays, upper skins and fuel tanks.

Engine, Radiator and Parts

We have made significant progress toward reassembling the Hurricane's Merlin 29 engine in the past quarter. The first significant challenge was to mate the heads with the cylinder banks. The job is complicated by the number of o-rings that are used to seal the coolant system between these two major engine components. The first head and bank assembly took five attempts, each taking most of a day. The second head and bank came together after three attempts. Numerous o-rings were pinched and cut in the process as was one head gasket.

After many attempts, success at last! Ken Pootz torques the cylinder bank to the head.

After reassembling the heads and banks, the next task was to install the pistons on the connecting rods, lubricate all contact surfaces with 100W oil and then with the use of an overhead block and tackle, lower the head and bank assembly over the pistons and on to the lower engine case. We are grateful to Bomber Command Museum engineer Greg Morrison for coming out on two successive Saturdays to guide us through this complex process. After all of the challenges with the head and bank assemblies, this part of the operation was smooth and faultless.

Greg Morrison aligns the pistons before we lower the reassembled head and bank on to the fourteen studs protruding from the lower engine block. The wartime manual says this operation requires just three people, but as we needed five, we are convinced that each of those three people had at least three arms.

Now looking much more like the V-12 she is, Ken torques down the second head and bank.

In the last quarter we reported that we had brought the engine radiator and oil cooler into Calgary for cleaning and pressure testing. We are relieved to report that the radiator, after having to seal just a few leaking tubes, passed the pressure test, saving us from the $50,000 expenditure for a new one. Unfortunately the radiator shop failed to recognize that although positioned in the center of the radiator, the oil cooler is a separate unit, they did not test it. When returned to HASI, it was found to be leaking badly and was again returned to Calgary where after being shuffled through two more shops, it was finally repaired and successfully pressure tested.

We would also like to acknowledge Canadian Aero Accessories for having repaired, function checked and painted various components for the Hurricane engine as well as the oil cooler, at no charge to the Society.

In this quarter we were also successful in acquiring a second authentic .303 Inglis/Browning machine gun. This one too is deactivated but is in better condition than the first one. The two we have acquired cost us an average of $1500 each. If need be, metal replicas are available in the same price range. A dealer in the UK offered us four more deactivated originals, but at $7500 each we declined the offer.

An Inglis/Browning AN/M2 .303 machine gun for the Hurricane. Yes, the famous washing machine company made guns: pistols, Brens and Brownings -over a million of them during WWII. Our model Hurricane carried twelve. This one is even dated 1942, which is when our airplane was built.

HASI put together a shopping list of parts which we forwarded to Hawker Restorations in the UK. Hawker confirmed by email that they had received the package and would let us know what they have available. The list is comprised of 51 'must have' items in order to complete the restoration.

Having exhausted all parts sources in Canada, it is necessary to go shopping offshore. The availability and speed with which these parts can be sourced may affect the completion date for the airplane.

HASI also discovered that a number of wing to fuselage and stabilizer to fuselage fairings which came with the Hurricane are in fact from a Cessna Crane. Given that the City's Hurricane and Crane were stored together we hope that the Aerospace Museum may have the corresponding fairings for the Hurricane. We have contacted their Executive Director and were told to be patient as building renovations were a priority for them.

Colour Scheme and History

Board member Andy Woerle continues to research and develop the paint and markings scheme for the Hurricane. We have had input from some of the world's leading authorities on the issue and are confident that we will be able to hand to HASI a three plan view, a text document detailing the precise colour scheme and markings as well as paint samples for this Hurricane as it served with 133 (F) Squadron between July 1942 and July 1943.

Our efforts to document the history of this Hurricane have sparked the interest of professional and amateur authors and historians in Canada, the UK and the USA. Over the past few months, we have received dozens of emails from Jerry Vernon, Jim Bates, Dr. Jon Leake, Norm Malayney, Terry Higgins, Gordon Riley, Carl Vincent and Mathias Joost, the latter with the Department of National Defence, Directorate of History. We are

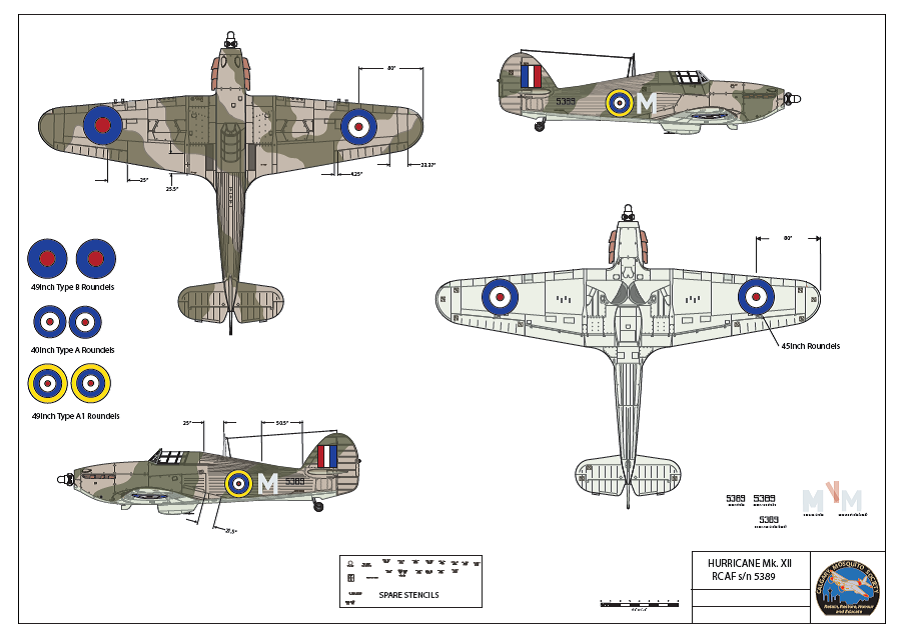

The three plan view of the colours and markings for the Hurricane, developed by Andy Woerle based on input from many sources.

very grateful to all for their considerable efforts on our behalf, especially Jerry Vernon who has spent dozens of hours poring over copies of original wartime record cards, transfer orders and station diaries. Our thanks to all.

These discussions and research reviews have unearthed some interesting issues. We have no manufacturer's data plate for this airplane and therefore have no way to prove its identity. This Hurricane has always been referred to it by its RCAF number as 5389 but without a data plate, this is an assumption. There is no evidence to suggest that this is incorrect, so until proven otherwise we will assume that this is its identity. As well, there is to date, no proof that it was aircraft "M" in 133 Squadron, though again, evidence suggests that this was the case.

Port side of the Hurricane cockpit. The black circle above the fuel selector valve indicates where the aircraft's data plate was originally installed, now conspicuous by its absence and leaving us without proof as to the aircraft's identity.

Jerry Vernon's research confirms that when Hurricane 5389 was struck off strength by the RCAF in 1946 that the engine which was installed at the time, Manufacturer's No. A-4687, is one of the two with us in Nanton today.

Wartime record cards researched by Jerry Vernon indicate that this engine, MFRS. NO. A-4687 was installed on Hurricane 5389 when it was struck off strength in 1945 and transferred to Crown Assets Disposal Corporation for sale. While strong evidence, it does not guarantee that our Hurricane is 5389 as two airframes were acquired and brought to Calgary at the same time, with the second Hurricane ending up in England by way of a group in Regina.

Jerry and Dr. Leake have also clarified for us that our Hurricane was built in 1942 as a IIB model but that the designation was changed by the RCAF in 1943 to XII. This and other Hurricanes have often been mistakenly referred to as XIIB models.

We have acquired a copy of the wartime Operational Record Book from 133 Squadron which details, on a day to day basis, which airplanes did what and with whom. With this document, we should be able to detail its time with the squadron, including which pilots flew it and who was responsible for the accident that saw it removed from the squadron for repairs in July 1943.

Ongoing research also indicates that our Hurricane was likely one of a small handful that were posted to airbases across the prairies in the spring of 1945 to intercept Japanese fire balloons that drifted on the jet stream across the Pacific Ocean with the purpose of dropping explosives, starting forest fires and damaging civilian morale.

Mosquito: Jack McWilliam

The fourth quarter of 2015 saw the skin replaced on the right side of the fuselage in the area of the dinghy box, just aft of the canopy. The inner skin was replaced in the same manner as was the left side with a number of lap joints. The ribs and stringers had already been made when we re-skinned the left side of the fuselage earlier this year. Those pieces are now being installed as well.

One area that had not yet been restored was the center line on either end of the dinghy box opening on the top of the fuselage. These parts required a piece of flat grain Sitka spruce rather than the standard vertical grain used elsewhere. We had already been looking for a source of spruce out on the west coast earlier this summer when inquiries led us to Doug Carl of Carlwood Lumber in Maple Ridge, B.C. After explaining our requirements, Doug and his father jumped into helping us. We drove out to Maple Ridge to get a piece of flat grain Sitka so we could continue building the ribs. Doug took the time to pull

Roger, Dick and Gary (inside the fuselage) fit and install the new inner skin to the right side of the upper fuselage, aft of the cockpit area. In the background David continues the work of stripping and restoring hydraulic components.

Looking down the center line of the upper fuselage, aft of the cockpit and dinghy box area.

Some exquisite planks for us to use, custom cut them to fit in my vehicle and donated them to the Society. The Mosquito Society is very grateful to Doug and his family for his support of this project.

Beautiful flat grained Sitka spruce from Carlwood Lumber in Maple Ridge, B.C. Probably some of the best in the world and too valuable to be left in the car overnight.

As I felt that the lumber was too valuable to leave in my vehicle, the staff at the Holiday Inn helped me store it in my room while I ran other errands on the lower mainland.

I was also on a quest for quality brass screws of various sizes, having talked to a few boat builders in the Vancouver area. Pacific Fasteners in Burnaby, B.C. had a large selection of brass screws, some of which were surplus Boeing Aircraft screws. They are notable by the significant layer of tarnish on the surface from their age and storage conditions. I personally think this is a nice touch to finally be able to install these screws into an aircraft.

Various components are being cleaned and restored for the fuselage by various local shops and volunteers in Calgary. Paul for example has been working on the fuel

distribution valve that is now ready for paint. The painting will be complete this week and reassembly will commence, or as the manuals put it "reverse procedure".

Tubing is being cleaned, selector valves have been dismantled for cleaning which are being plastic bead blasted by Aviation Solutions Inc., of Calgary. ASI will deal with more parts after the Christmas break; after which we can prime and repaint these components.

We have re-fitted the canopy frame to the fuselage at this time to act as a stiffening fixture while the structural damage to the starboard side of the forward fuselage is

The canopy frame being temporarily reinstalled to stiffen the fuselage in this very vulnerable area while we evaluate the damage to the starboard side in front of the wing cut out area.

assessed and repaired. At this point the fit of the canopy frame is not correct and we are working to determine if the frame is bent or if the fuselage is twisted. Bear in mind the front wind screen was smashed by repeated blows many years ago, which may have distorted the frame. A side note to this is that when we were moving the fuselage from the City warehouse to Nanton on an open flat deck trailer in August 2012, Richard commented on the fact that it appeared the canopy assembly was not attached to the fuselage at all. To our surprise he was correct and it is now a bit of a joke about how it would have looked had it landed on his car as he followed closely behind the trailer at 110 km/h.

Displays and Presentations

Though there were none this quarter, we continue to play tour guide to weekend visitors at the Bomber Command Museum.

Board member Brian Collins takes time out on a Saturday to talk to visitors about the restoration of the Hurricane's Packard Merlin 29 engine.

A key activity of the Bomber Command Museum are their special event weekends through the spring, summer and fall months which all feature, among other things, the Lancaster engine runs. This coming June 4th, the theme for the day will be Mosquito Celebrations, acknowledging the 70th 'birthday' of our airplane and the 75th anniversary of the first flight of a Canadian manufactured Mosquito. The day will feature cake, presentations and lots of Mosquito themed merchandise and events.

Miscellaneous and In the Works

On November 14th all of the staff of Aviall Calgary (A Boeing Company) chose us and the Bomber Command Museum as the organizations to which they dedicated a days' worth of giving back to the community through staff volunteer efforts. Lots of cleaning, sorting and picture taking took place that day. Our thanks to all the staff who volunteered and to the "AviALL Partner in the Community" program.

Jack spends a few minutes with the staff volunteers of the worldwide aviation supply company AVIALL before putting them to work for the day.

Pan Productions, our video producers, have presented us with the final cuts on the videos we commissioned with them in late 2014. The contract called for them to produce fifteen short films on each of the two airplanes in support of our mandate to "Honour and Educate". Their genuine enthusiasm for this project has resulted in the production of thirty five videos, with the additional five at no extra cost to us. At our request Pan is now adding closed captions to all of the videos.

We are also in the final stages of selecting a touchscreen kiosk on which to display the videos. This unit will be set up adjacent to the Mosquito for the balance of the restoration period for visitors to select and view the videos of their choice.

The Q10 Freestanding Kiosk with 32” Touchscreen, built in PC, etc., from Slabb Inc.; one of the styles we are looking at to show our newly produced videos.

As well as the onsite kiosk, we will upload all the videos to our YouTube channel so that they are available to anyone with an interest. Recognizing that some people would still like to own them, we are having an initial run of 100 DVD copies produced for sale as well.

The kiosk, YouTube upload and DVDs will all be complete and available in the first quarter of 2016.

<

Richard de Boer, President

January 11, 2016