Click on any image for a slideshow!

Progress and Activities from

July to September 2016

Here is the latest news from the society about restoration progress on the Mosquito and Hurricane, new merchandise, special event days and activities. Enjoy!

Volunteer Hours

Over the past three months, board members of the Mosquito Society invested a total of 195 hours during the third quarter of 2016 on all duties required to run the organization.

Additionally, members of the society worked 1469 hours on the Mosquito and 23.5 hours on the Hurricane over the same period on 27 separate dates in Calgary and in Nanton.

Note that the volunteer hours on the Mosquito are again at a new record high, but as we have completed and delivered the Hurricane's engine, our hours on that project have dropped significantly.

Total volunteer hours for this quarter are 1687.5.

Hurricane

Historic Aviation Services' focus for the third quarter of the year has continued on the sheet metal areas of the forward fuselage and on the woodwork from the cockpit back to the tail, which significantly fleshes out the look and shape of the airplane.

We were in Wetaskiwin on September 30 to conduct our quarterly inspection of the project.

Airframe: Historic Aviation Services

Fuselage

- Utilizing permanently installed upper fuselage "turtle deck" as a reference, we fabricated port and starboard cockpit sills (originals missing).

- Fabricated, primed and sprayed with silver butyrate, the port and starboard cockpit sill mounting brackets (originals missing).

- Cockpit sills varnished and top surfaces given 2 coats of green epoxy.

- Port and starboard cockpit sill assemblies mounted in place.

- Finished fabrication of port radio equipment access door.

- Fabricated starboard radio equipment access door (originals missing).

- Fabricated starboard battery rack access door (originals missing).

Radio access doors for the port and starboard sides of the fuselage as well as the battery access door. All made from scratch.

- Fabricated, primed and sprayed with silver butyrate, the lower port and starboard fuselage side former mounting brackets (originals missing) and installed same at former stations 4, 5, 6 and 7.

- Finished fabrication of port and starboard fuselage side formers and installed in position.

- Fabricated wood framework for fuselage access panel under horizontal stabilizer, port side.

- Fabricated, primed, sprayed with silver butyrate, mounting brackets for port rear fuselage access panel (originals missing).

- Mounted complete port rear fuselage access panel framework in place.

- Marked out locations and notched port and starboard fuselage side formers for stringer attachment.

- Installed all port and starboard side fuselage stringers.

Fuselage formers and stringers all installed. Sadly all of the wood is sprayed with silver butyrate dope as per the original by Canadian Car and Foundry.

- Finish, fit and sand all of side fuselage stringers for conformity.

- *Note: All woodwork described above were given two coats of "Polyfiber" epoxy varnish and sprayed with two coats of silver butyrate as required during build up process.

- Fitted intermediate belly panel purchased by the CMS from a vendor in England into position - fits nicely. This panel is basically usable with minor wood repairs, hardware installation (original items missing) and fabric recover. This panel now provides a reference for the location and fabrication of the missing panels forward and aft of it. As a point of interest, this panel originated from Hurricane LF 363; one of the Battle of Britain Memorial flight aircraft.

Parts purchased from Spitfire Spares in England include the lower fuselage wood panel, pilot access door, undercarriage door and compass tray.

- Located, cleaned, repaired, primed and sprayed with silver butyrate, ten fuselage belly panel mounting brackets. Mounted same in position.

Propeller and Hurricane Parts

We gave Aero Propeller (Calgary) the word to start the overhaul on the Hurricane propeller early this quarter. We had held off until recently as a finished and assembled propeller takes up a lot of space. We stopped in recently to discover that no prop dome was included with what we received with the project and consequently the propeller overhaul could not be completed. Shop owner Gord Thompson advised us that his regular parts supplier for these 75 year old items no longer carried them.

I spoke with Byron Reynolds who thought he might have one and Jack McWilliam spoke with Herb at the Aerospace Museum. Both Jack and I came up with the necessary dome. In fact the Aerospace had three. We delivered two of these to Aero Propeller who will use the best of them on the Hurricane propeller. We expect it to be completed before year end.

As stated above and in last quarter's report we located a vendor in England who had a stock of Hurricane parts. From them we purchased a section of fuselage woodwork, a pilot's door, a compass tray and a piece of the main undercarriage door. Historic Aviation Services were very pleased with all, estimating that the purchased ultimately saved us time and money. We approached the same vendor about some other items and are awaiting his response.

As we know, this model of Hurricane carried twelve .303 Browning machine guns. To date we have purchased three and managed in this past quarter to located two more. That said, having been looking for four years now, it seems unlikely that we will acquire the remaining seven. With that in mind we have been working with several gunsmiths and machine shops to see about having metal replica guns made. So far quotes have come in at $1550 US and $2650 Cdn. We are awaiting a quote from a third party before deciding how to proceed.

We have arranged for the exhaust pipes to be returned from Acorn Welding in Edmonton after their initial offer of assistance turned into an expensive quote for the repair work on them. We will return the pipes to Vi-Scan who have offered to do the weld repairs at no charge.

We are still challenged by parts issues on the Hurricane and are working hard to find the internal parts of the main hydraulic selector, numerous specialty fasteners and the balance of the rails for the canopy.

Historic Aviation Services is now projecting completion of the Hurricane for late 2017.

Mosquito: Jack McWilliam

Repairs continue down the left (port) side of the fuselage, repairing inner and outer skins. The damage to the fuselage forward of the rearmost porthole has been repaired. This was not without unforeseen challenges as the stringer between the inner patches was warped inward. The stringer was unglued from the inner skin, strapped to a straight edge for a period of time, re-bonded to the new inner skin while clamped to a straight edge, but with no success. A work around is now ready and will be incorporated.

The last patch around the forward porthole has been removed with more issues under the skin, moisture damage, more cedar and internal damage from parts being ripped out of the aircraft.

On the left side of the fuselage between the two portholes. The skin was removed to deal with damage and previous poor quality repairs.

The area will be repaired in the same manner as the previous skins by lapping in new material. Internal forms again will be constructed to hold the structure in shape.

Further aft, a form has been tested to jack out the skin and stringer on the right hand side that has been pushed in. This turned out to be a bright spot for a change; it was believed to be a cracked stringer, but later turn out to be a far less serious broken scarf joint.

Inside the rear fuselage. Everything in red was designed to create support for the monocoque fuselage structure while we replace old patches and repair stringers.

New LED lights were installed to cut down on the heat and to provide better illumination in the working area.

We have done away with all of the hot work lights and replaced them with LED strips which are far safer and provide much better lighting inside the fuselage.

Various components from the hydraulic pack have been cleaned, now being ready for painting or plating. Cockpit components from the floor boards have been stripped and are ready for painting.

Under the cockpit floor area is being cleaned of oil and debris with attention being given to areas that have gone soft from hydraulic fluid being absorbed. An area of concern is below the emergency valve.

The bulkhead in the area of the crew hatch is badly damaged with loose glue joints. The plywood laminates for the bulkhead in the area of the crew ladder have been replicated and will be fitted around the rib, preserving the original rib. The original rib has some unique wear marks in it from the crew ladder repeatedly being stored, which resulted in eventually cutting out the rib.

As described in the text above and below this is the area beneath the cockpit floor where we are dealing with worn, broken and delaminating bulkhead problems.

The rib for the crew ladder bulkhead also represents an example of the rib coming off the primary structure. We have one person focused on each end of the cockpit, inspecting, cleaning or re-bonding various parts. These parts could be delaminated, damaged or very poorly made in the first place. The attach point for what would have been the bomb site mount was over a ¼ inch out of contour.

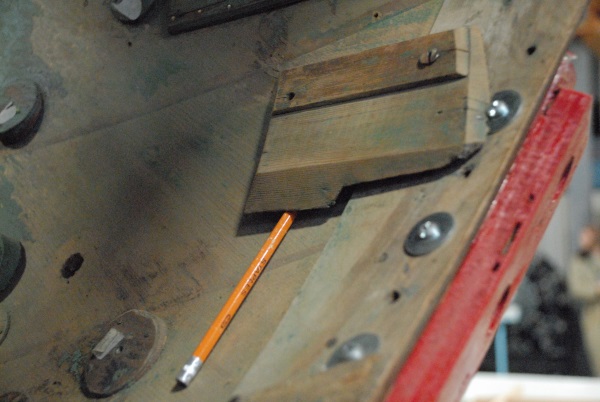

The pencil demonstrates how far the bomb site mount is out of contour with the inside of the fuselage. This is the result of very poor workmanship when the airplane was built in 1946.

Experiments are under way to establish a process to cut scarf joints in the original skins still attached to the fuselage. We have built a router shoe that follows the curve of the fuselage with a 12 to 1 tilt on it. The router is then guided along by fences made of puck board which are clamped in position to the fuselage. With some changes we are hoping this will allow us to move forward with installing new skins to the existing skins.

Parts

In this quarter we purchased two parts collections from the UK. The first was from David Coeshall who has for many years been a Mosquito 'super fan', and was the co- organizer of the most recent Mosquito Aircrew Reunion events. As part of his interest in the type, David had acquired parts from many sources over the years. He parted with his collection in favour of seeing it go toward the restoration of our airplane. It contains some excellent material such as instruments, gauges, lights and much more.

Tail wheels, landing lights, airspeed indicator and fuel gauges. All part of the collection acquired from David Coeshall. Many parts here that we did not have.

The second collection was purchased from Tony Bianchi of Personal Plane Service who is one of the founding fathers of the warbird movement in the UK. His collection of Mosquito parts goes back to when he was involved in maintaining the airplanes for the filming of the classic Mosquito movie, 633 Squadron in 1964 and the less than stellar Mosquito Squadron released in 1969.

Lionel looks over some of the parts acquired from Tony Bianchi, including a sextant, oil pump, hydraulic rams and radios. These parts have some very cool movie history attached to them.

Since deciding to clear his hangar and retire, Tony has been inundated with offers from collectors to buy these parts. Tony turned down all such offers, preferring that they go to an organization that would use them in a restoration, rather than see them scattered among collectors as souvenirs.

Displays and Presentations

As always, this is a busy quarter for special events. On July 9, the Bomber Command Museum held its annual Bikes and Bombers event. On all of these occasions most of

The annual 'Bikes and Bombers' event at the museum attracts hundreds of two wheelers and is always a financial success for us as bike owners spend money.

the work on the Mosquito gets set aside as we focus on visitors, giving tours and answering questions. Coinciding with Heritage Day on August 1st, it was Nanton Parade Day, which sees one of the busiest days of the year at the museum.

CMS Vice President Jack McWilliam takes time to talk to visitors about some of the restoration challenges on the Mosquito during one of the many special event days throughout this past quarter. It's all part of our broader mandate to 'Honour and Educate.'

The third weekend of August always sees the biggest event of the year for the Bomber Command Museum with a Friday night party and Lancaster night engine runs. The theme for this year was the celebration of the museum's 30th anniversary. The last major event of the season was on September 16 and 17 which focused on efforts to salvage and restore a Halifax bomber for the museum.

Lancaster night run; part of the Museum's 30th anniversary celebrations, Aug. 19 and 20.

Not a lot of restoration work gets done on special event days as we spend most of our time talking to visitors. Our hosts at the Bomber Command Museum have told us that a large percentage of visitors come in specifically to see the Mosquito which has become one of their most popular attractions.

We again participated in the annual Historic Calgary Week (July 22 - Aug. 1) activities by doing a lunch time presentation at Central United Church on the history of the City's Hurricane. We had a good turnout of 88 people to hear the first ever telling of the history of this airplane.

This year the Canadian Business Aviation Association held their annual convention in Calgary from July 5 to 7. Months before the event, the CBAA approached us with an invitation to set up a booth and a display at no cost. They see us as adding an unusual

Our display booth at the CBAA convention in Calgary, July 7. We were given a prime spot and a double wide space. Our displays generated lots of interest.

and attractive dimension to their very highbrow event that attracts the world's leading business jet manufacturers and business aviation leaders. We take it as a mark of favour that they provided us with a double sized booth in a very choice location. We had a very busy day talking to visitors and attendees of this prestigious event.

The CBAA convention attracts business jet manufacturers such as Bombardier, Gulfstream and Falcon.

Miscellaneous and In the Works

We added a new design to our stock of t-shirts for sale. Although we offer them to the public, this one was designed more for our core volunteers working on the Mosquito. It came about as the result of accusations by one of the Calgarians supporting the sale of the Mosquito to the buyer overseas when he accused our group of being nothing more than "overenthusiastic amateurs" who suggested that we would likely restore the airplane with two by fours and auto body filler. We decided to turn those accusations into a badge of honour.

A new t-shirt design by the CMS inspired by accusations made during the campaign to save the Mosquito and see it finally restored.

At the end of July we had a visit from David Dorosh who was an apprentice engineer with Spartan Air Services, based in Edmonton. David came with a binder full of information about Spartan, including every company newsletter issued between September 1957 and July 1959.

Ex-Spartan engineer David Dorosh poses with the vertical tail of our Mosquito. His first ever flight in a Mosquito was in our very own CF-HMS.

David has proven to be an invaluable resource not just on the history of Spartan but on some of the technical details of the Mosquito, filling in blank spots in our knowledge and educating us as to some of the Spartan modifications on the Mosquito.

Our restoration projects continue to attract attention from many people around the world including some notable aviation figures. On August 10, we hosted a visit by airline founder and Aviation Hall of Fame inductee, Max Ward who came to Wetaskiwin specifically to see the Hurricane.

Byron Reynolds (right) talking to Canadian aviation legend and founder of Wardair, Max Ward about the restoration work on the Hurricane.

At age 94, he is mentally sharp and did not hesitate to climb onto ladders and platforms for a closer look at the work being done on the airplane.

<

Richard de Boer, President

October 9, 2016