Click on any image for a slideshow!

Our Q3 Report: The busy months of July, August and September

Volunteer Hours

Board members of the Mosquito Society worked a total of 202.5 hours during the third quarter of 2017 on all duties required to run the organization.

Additionally, members of the society worked 1435.5 hours on the Mosquito and 27 hours on the Hurricane over the same period on 28 separate dates in Calgary and in Nanton. Total volunteer hours for this quarter are 1665.

Financials

In July we completed the final report for the $15,000 grant from Veterans Affairs Canada for video production. As soon as it is reviewed and approved we will receive the final 10% holdback payment of $1500.

We also completed the final report for Alberta Historical Resources Foundation of Alberta Culture and Tourism for the two $25,000 grants for the Hurricane and Mosquito. The report was followed up with a site inspection on both projects by a representative from AHRF. We expect a cheque for the full $50,000 within the next month.

In late September we got word from WestJet that they were donating another pair of 'fly anywhere' airline tickets for us to raffle off. This will be our third such raffle. We traditionally sell 2000 tickets at $5 each.

In mid August we received a cheque from the Alberta Gaming and Lottery Commission for the casino we held on May 31 and June 1 in the amount of $64,719.72.

Hurricane

A great deal of time and focus has gone into the last part of the Hurricane structure to be completed prior to focussing on the aircraft systems. This is the doghouse, canopy, windscreen and door area around the cockpit. Given the difficulties we experienced in acquiring a doghouse, plans for a doghouse, canopy rails, canopy panels, etc., this area, which in the order of restoring the airplane should have been completed far earlier in the process, now ties together the front, rear and sides of the fuselage.

The doghouse, canopy, windscreen and door area around the cockpit.

In a recent Facebook post, I noted the number of individuals and organizations involved in bringing the parts and knowledge together in order to complete this area of the airplane:

"The armoured windscreen, although manufactured in Canada in 1942, was located in England by our good friend David Coeshall. The door was purchased from Spitfire Spares in the UK after it was spotted on their website by CMS member Ken Pootz. The Perspex panels were acquired for us by Aircraft Restoration Company from Hawker Restorations Ltd. Although requiring significant correction by HASI, the structure of the doghouse was built by volunteers at The Aerospace Museum many years ago. Plans to allow us to finish the doghouse were supplied by our friend Ron Taylor, and very importantly Brian Davis, (both in Ontario and both contacted us because of our Facebook presence) based on work done by Harry Whereatt of Assiniboia, SK. when he was working on a Hurricane in the 1980s. The canopy rails were manufactured for us in Chino, CA by a machine shop located by our VP, Jack McWilliam. Doing the work to bring all of this together is the very talented Greg Davis of Historic Aviation Services with half of the funding provided by City of Calgary with the balance of funding provided by Calgary Mosquito Aircraft Preservation Society and all of it coordinated by us."

All of these people, organizations, knowledge and effort were required for just one area of the airplane.

Our efforts to obtain parts from various vendors in England have met with very limited success. It seems the barriers against us trying to source Hurricane specific parts are still in effect. We acquired just six items from the original list of 56 'must have' missing items. We have exhausted all possible avenues for acquiring the needed parts in England.

Fasteners for the gun bay doors. Each is comprised of six different parts, five of which must be machined or milled. Producing just 20 of these consumed one month's labour.

Historic Aviation Services is now resorting to manufacturing and machining what we cannot obtain. This includes fasteners, handles, latches, etc. On my most recent visit, I learned that producing just 20 fasteners, each composed of six pieces, has taken one months' labour to produce.

We made our quarterly inspection visit to HASI on October 6.

Airframe: Historic Aviation Services

Fuselage and Center Section

- Continued modifications to previously built upper, forward fuselage doghouse assembly.

- Finished fabrication of missing doghouse formers and semi bulkheads. Installed same in place as required.

- Manufactured and installed missing cockpit sill clamps.

- Varnished and painted inner surfaces of main doghouse assembly with silver butyrate and fitted same to cockpit section of fuselage.

- Jigged and secured windscreen framework in place.

- Connected upper fuselage wood stringers to doghouse and secured entire assembly in place. Touched up glue, varnish and silver butyrate as required.

- Began fabrication and fit of port and starboard rear canopy rail beds. Note that Emergency canopy eject components missing so canopy rails will be fixed in place.

- Began fabrication of port, forward doghouse to firewall cockpit woodwork.

- Began fabrication of glare shield woodwork (above and forward of instrument panel).

- Clean, etch, prime and fit pilot's head armour plate to forward face of cockpit doghouse.

Pilot's headrest armour plate trial fitted to the front of the doghouse. Prior to install it was stripped, primed and painted.

- Began repairs to starboard side cockpit emergency door (used item obtained from England).

- Machined missing hydraulic reservoir hand pump unit, inlet and outlet fittings and filler cap and fitted same to unit.

- Began manufacture of missing access panel, spring loaded fasteners.

- Began fitting out of cockpit with the following supplied from HASI inventory, all of which was repaired and tested as required:

- 1. Magneto switch, ref. # 5C/548

- 2. Push button start switch, ref. # 5C/695

- 3. Qty 2, single toggle switch, ref. # 5C/543

- 4. Triple toggle switch, ref. # 5C/544

- 5. Dimmer switch, ref. # 5C/367

- 6. Landing light switch, ref. # 5C/623

- 7. Qty. 2, cockpit light assembly, ref. # 5C/366

- 8. Identification light switch box, ref. # 5C/372

- 9. Manifold pressure gauge, ref. # AN5770-01

- 10. Fuel quantity gauge, ref. #6A/632

- 11. Outside air temp gauge, ref. # 25187

- 12. Engine triple gauge (oil/fuel pressure and oil temperature), ref. # AW 2 3/4 -19 - Z

- Machined adaptor fitting to mate oil temperature probe to Merlin engine.

Magneto switches, Hurricane specific fuel gauge and identification light switch box; all supplied by HASI.

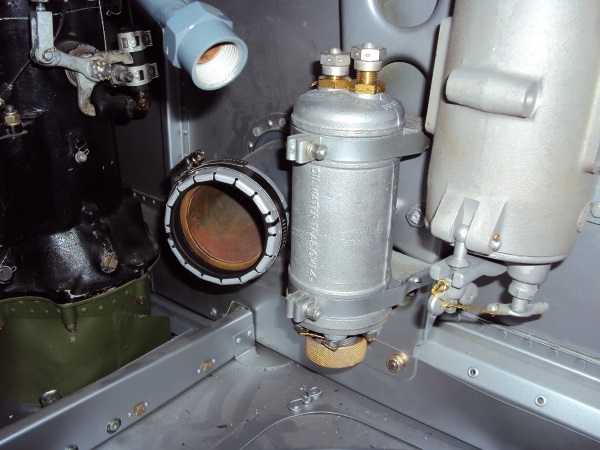

Finished overhaul of air system oil/water separator unit, installed same in position on forward face of center section front spar.

Empennage

- Finished cleaning and inspection of port and starboard, elevators, rudder, horizontal and vertical stabilizers.

- Began rib repairs to all above as required.

- Began leading edge repairs to all above as required.

Mosquito

As opportunities present themselves we continue to acquire parts and resources to assist in the restoration. In June we were contacted by a couple in Nova Scotia who spotted at a garage sale what they thought was a Mosquito nose blister. Through some misunderstandings they acquired it for us and in turn one of our members purchased and donated it to the society. It is not the right style for our aircraft, but it is great trade material.

Newly acquired Mosquito nose blister. Many Canadian built Mosquitoes were posted in the Maritimes during the war in Operational Training Units.

The component shop of Sunwest Aviation in Calgary was good enough to disassemble and inspect two spare tail wheels for us as we were looking for a potential serviceable unit to trade to the Mosquito Bomber group in Windsor, ON.

Making international news in August was the incredible discovery of 22,300 drawings and plans for the Mosquito in an Airbus plant in England that was slated for demolition. The Peoples Mosquito organization, with whom we have had an affiliation for some years, gained worldwide attention with this find. They have begun the process of indexing and cataloguing the find, which contains many one of a kind technical drawings for repairs and modifications, many of which were considered but never developed. It also includes repair schemes for the prototype Mosquito.

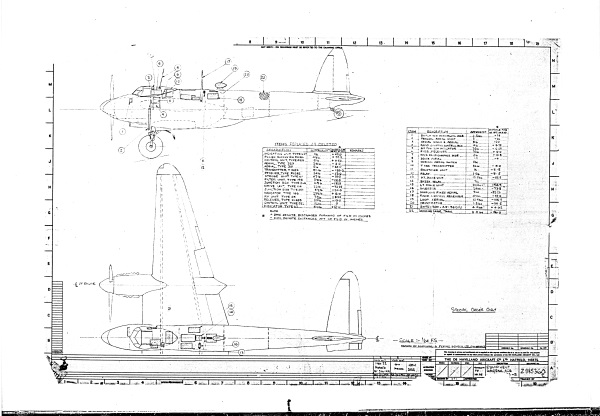

One of the drawings from The Peoples Mosquito group showing the modifications required to convert a B.35 model Mosquito into a PR.35.

The organization contacted us when they discovered the drawings, developed in 1950 by Marshall's Flying Club of Cambridge, to convert the B.35 Mosquito model into the PR.35 model at the request of the Royal Air Force. Our airplane was the very first to undergo these modifications, thus becoming the prototype PR.35. The chief engineer for The People's Mosquito group took time from his indexing work to copy two sheets and send them to us, making us the first organization to benefit from this historic find.

Jack McWilliam

We will start from the tail of the aircraft and move forward. We have started to build work stands around the aft left side of the fuselage to facilitate access to the top side area.

Externally there are two skins that require removal, one small and one large. From past experience we are confident they are very poorly bonded to the internal structure.

It is my opinion we have lost about 70 to 75 % of the adhesion and worse still was where the birch contacts the balsa. This has been consistent throughout the aircraft at this point. As well, the inner skin is suffering from the hundreds of staple holes which were used to clamp the skins together in some earlier crude restoration attempt. At this point I am hoping we can lay a new skin over the old structure as we had previously done in other areas.

On the inside rear of the fuselage, Don Y. has been cleaning and removing components so we can determine the level of damage around the tail wheel attach points. The area between the two aft bulkheads has a different issue than the rest of the fuselage. The area, which had large amounts of dirt and oil, was simply varnished over at some time and now has the texture of 60 grit sandpaper.

Down the left side of the fuselage all the balsa that was damaged has been replaced. There remains a small section on the right side which will be completed within a week. Andy and Cam have about one days' work left to finish the balsa on the right side so they can move on to other areas.

Andy and Cam applying T88 epoxy glue to the new strips of balsa wood on the port side of the fuselage.

Michael, Don and Davey have moved aft to bulkhead 3 were work has commenced on the structure which contains the lower wing attach points. It seems a normal thing for aircraft; all but one bolt has been removed from the left side. There is a large amount of rust and we will look closely at the bolts with the thought of installing new hardware in those positions since they are crucial to securing the wing.

In the same area, the lower forward skin on the bulkhead has been removed with very little trouble thanks to poor bonding. The skin has been cleaned, the ribs are cleaned and the area is masked off for painting. It did not have paint originally but in the interest of protecting the area we have decided to cover it over. As well, it will be caulked on the aft side with epoxy to reinforce the back side without removal.

The Spartan modified lower half of bulkhead 3 with the front face removed. To the right are the mounting brackets that seem to defy logic in how they were installed. As per the text below, we pioneered a new technique to clean them.

The removal of the skin has given us a couple of benefits, one being the removal of the steel nails that were rusting and exposure to the inner structure. This area is not original to the aircraft at build, but was redesigned and modified by Spartan Air Services as an add-on for the Wild camera mounts, making it unique to our aircraft. We are still trying to figure out how it was put together as the attach brackets overlap. We have theories, but not a conclusive answer.

A new method for paint removal on those attach points has yielded success; Wayne had suggested using an airbrush eraser. The process is slow but we achieved the results we need using a media of baking soda, both cheap and user friendly as opposed to the more conventional aluminum oxide.

The canopy frame installation work has stopped as we require the external skins to be fitted before the rest of the material can be installed. We continue to go over the cockpit area looking for loose corners and bad joints before paint is applied. Various small gussets and spacers are being removed cleared and reinstalled there again because of the poor bonding issues. Andy has all the original ferrules installed with a small number of missing to go.

Gary and Dick concentrate on the canopy frame area while Davey continues to work on the crew entry hatch area.

The structural repair work in the cockpit area is slowly coming to completion with small areas being glued following close inspection. The last remaining large job is to complete the tunnel from the main crew entry door to the floor boards.

Gary has the components done and he flips between that and the canopy frame work depending on whom else is working where.

Paul and I are currently cleaning and painting various metal parts with Davey putting them back on templates.

Two areas that are holding us up are the tap and dies, as well as gaskets. The tap and dies have been ordered from a tool manufacturer in eastern Canada with scheduled delivery early in October. We have to go down the road of British Association, British Standard fine and British standard Whitworth so one set of each is on its way. Remembering that the British method of safety is to hit the end of a bolt with a hammer (calibrated size) rather than use a split pin with the result that all the bolts are galled on removal and require the threads to be cleaned before reuse.

On the gasket side, a local company has volunteered to make gaskets for us but we need to supply them with templates which we have yet to make. The gaskets are required for where metal parts are mounted inside the wood fuselage.

With the summer season complete we will get back to physically spreading out a little with a few more projects on the go. The side panels will likely be brought over before the snow flies so we can start on the components attached to the sides. We have been busy fixing some of the tooling as well, such as the bead blaster to get up to speed with cleaning things like the wing attach components.

The crew are now taking some satisfaction in the discernible progress in many areas; we can now see a lot of the little things that have been accomplished. The cockpit is approaching the point where we will start painting, much to the chagrin of most involved as we are the only ones that appreciate the long hours that have gone into repairing, cleaning, and preparing the beautiful wood surfaces, only to have to cover it all with paint.

After hundreds of hours invested in paint stripping, cleaning, and restoring the wood of the cockpit area, there is some reluctance to paint this area and hide all of the good work and beautiful wood.

Events and Miscellaneous

This quarter is our busiest in terms of public events and spreading the 'Honour and Educate' word. We kicked it off with Canada 150 Day at the Bomber Command Museum which included the usual Lancaster run ups and Bristol Hercules engine runs. The weather was great and the crowds were big. As usually happens on these event days, our volunteers spend more time talking with visitors than working on the Mosquito.

Canada 150 Day celebrations brought out hundreds of visitors and always means we spend our energies talking with people about the Mosquito; its history, significance and our progress on the restoration.

This was followed up three weeks later with the Bikes and Bombers event on July 22. Again the weather cooperated and we likely saw the largest number of bikes and bikers yet for this event which is now into its fourth year. Some of the vintage car clubs heard about the fun and filled the baseball diamonds adjacent to the museum as well.

The annual Bikes and Bombers event, July 22. We were blessed with perfect weather and a record number of bikes for this event.

The following weekend, July 29 and 30, we were in full display mode for two days at the Wings Over Springbank Airshow. Organized chiefly by board members Jack McWilliam and Colette Provost, we set up a tent, tables and displays to spread the gospel to the many visitors over the weekend. We had a prime location on the walking route from the parking lot to the flight line and were kept very busy for two days talking Mosquito and Hurricane history and restoration progress.

Two great days at the Wings Over Springbank Airshow, chatting with visitors about our projects.

On August 3, we participated in the annual Historic Calgary Week by presenting a lunchtime PowerPoint at the Central United Church on 7th Ave and 1st Street SW to an audience of approximately eighty five.

Since our inception, we have maintained a very good relationship with the Canadian Business Aviation Association. Over the past ten years we have attended all three Calgary hosted conventions and in 2016 we were awarded an associate membership to this national organization. We put on a good display and bring a colourful and unique presence to their multi-million dollar business jet focus. Their convention this year was slated for Abbotsford, B.C., August 9 to 11, to coincide with Canada's largest airshow. Our vice president Jack McWilliam took some vacation time and loaded his car with display materials in order for us to be represented. While there, representatives of the Abbotsford Airshow committee asked Jack if he would set up our display for the airshow itself. Lack of additional support and some long days meant having to decline the flattering invitation. We will consider it for next year.

Vice President Jack McWilliam took a weeks' vacation to attend the CBAA convention in Abbotsford, BC on our behalf.

The following week we were very active again with the Bomber Command Museum's biggest annual event of the year, this year celebrating the 75th Anniversary of 6 Group of Bomber Command. The weekend kicked off with a Friday night social event and a Lancaster engine run in the dark.

Months before this event we had been contacted by author Mark Nelson of Sydney, Australia, who in his 2012 book, MOSQUITO, featured the post war work of Spartan Air Services and of our airplane in particular, rather prominently over four pages.

Mark managed to be in Nanton for the kickoff evening of the weekend and after years of correspondence, to make some face to face contact with us.

Saturday was highlighted by guest speaker Lt. Col. (Ret.) David Bashow, author of several books on Canadian military aviation history, Senator Anne Cools, airplane smoke and noise and lots of interactions with visitors about the history and restoration progress of the Mosquito and Hurricane.

Author Mark Nelson came up from Sydney, Australia with a copy of his book MOSQUITO in which our airplane is featured.

Four weeks later, on September 15 and 16 the Bomber Command Museum hosted an event featuring the Canadian Aviation Artist Association and updates on the salvage and restoration of a Halifax bomber.

Canadian Aviation Artist held their annual get together in conjunction with the Halifax themed weekend. Right: Senator Anne Cools addresses the audience which included two air cadet squadrons.

The next weekend, we travelled up the road to provide a modest table top display for the Foothills Flying Club Breakfast Fly-In event in High River, AB. The latter half of the day features a massive 'show and shine' car display throughout the town. This year saw over 1200 cars on display as the centerpiece of a day long party

the length of main street, in adjacent parks and on numerous side streets. As we have learned over the years, there is not a lot of distance between car fans and airplane fans.

Board member Barry Davidson checks out the breakfast at the Foothills Fly-In event at the High River airport, September 24.

<

Richard de Boer, President

October 8, 2017