Click on any image for a slideshow!

Mosquito and Hurricane biz in the First Quarter of 2019

Wow!

When your nose is right up against the bark, it's hard to see the forest. Or in this case, working on the airplanes two days a week and doing the almost daily administrative work makes it hard to see what sort of progress we are making. Doing these quarterly reports gives me the chance to step back and see how much we do in a relatively short span of time. And it stuns me every time I do a report to recognize how much we get done and how many hours supporters and volunteers invest in our project. Cool stuff.

In reality, we put in a huge amount of time. In the first three months of this year, volunteers have already put in a total of 2027.75 hours which is the second highest number of hours for a quarter since we began work on the airplanes in August 2012. Great work, thank you gang!

And just for comparison, here is what our birds looked like just a year ago:

No wings, no cowlings, no fabric skins, no rudder and tables full of loose little bits waiting for a good home.

Port side of the rear fuselage with new balsa core, but no new skins yet.

Green is good and there was none of it inside the rear fuselage a year ago. New green paint means that all structural repairs have been completed in an area and we can begin to install parts and systems. Not ready yet, last year at this time.

Now keep reading to see where things are at today.

Hurricane

We conducted our quarterly inspection of the Hurricane on March 29 in the company of Gordon M. Hill, the last surviving wartime pilot of this airplane. More on this under the 'EVENTS' heading below.

We are again indebted to our friends in Ontario, Brian Davis and Darrell Brown for their willingness to contribute parts from their Hurricane projects, after we fielded some '911' calls from Historic Aviation about recently discovered holes in some of the airplane systems. From Brian we acquired an oil pipe, complete with end fittings, of a type that are not available in North America. Darrell came to the rescue with a landing light as we were short by half a pair. The willingness and generosity of these gentlemen cannot be overstated. Our thanks to both.

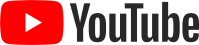

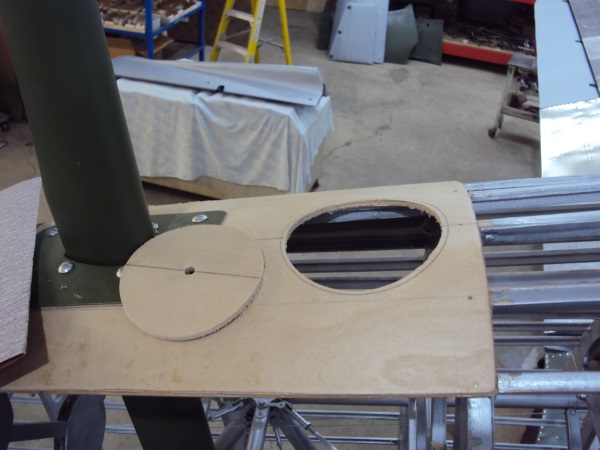

Oil line and fittings, upper, courtesy of Brian Davis and landing light, lower, from Darrell Brown.

We are pleased that a bookshelf souvenir from my airplane hunting days will fill a blank spot in the wing, as we required a gun camera to help complete the airplane.

Thanks also to friend and supporter David Coeshall in England who on our behalf acquired an Emergency Boost Control and an Undercarriage Indicator from a vendor in the UK.

While it has been a point of pride that we have been able to acquire a full set of 12 original Browning .303 machine guns for the Hurricane, we have to admit that several of them were missing a number of pieces such as forward mounts and butt plates. Thanks to board member Don. H. and Mosquito crew regular Michael H., who, through two machine shops, have managed to get multiple copies of several missing pieces

Newly machined parts for our .303 Browning machine guns. These bits will allow us to complete all the guns for the Hurricane as some came to us missing some parts. Thanks to Don H., Michael H., Tekoa Research and Rick at Alberta Tactical.

Airframe: Historic Aviation Services

Fuselage and Center Section

- Fabricate, assemble and install complete engine breather system including all fittings, brackets, tubing, hoses and clamps. Route same from engine crankcase to lower tail fairing exit aft of tail wheel.

- Repaired 12 volt starter motor assembly as required; remove 24 volt unit and install 12 volt unit in place. [Ed: 12 volt starters for Merlin engines are very rare items. Our thanks to the Bomber Command Museum of Canada for taking our 24 in trade for their only 12 volt starter].

- Supplied upper identification light from HASI inventory as original was missing.

- Fabricated upper ident light bucket mount (original missing).

- Assembled upper ident light unit and installed in upper fuselage forward of radio antenna mast.

The components of the upper fuselage ID light. They need to be cleaned, repaired, primed, painted, wired, tested, assembled and finally installed in the cut out area at lower.

- Clean, prime, paint and install, quantity 2, support brackets for port side cockpit fuel and vent lines.

- Cover fuselage with Poly Fibre fabric using STITS process up to silver.

- Applied green/brown Poly Fibre, Aero-Thane to various surfaces that will be enclosed/covered by panels and fairings.

Beginning the many step process of applying fabric to the fuselage.

Many steps later after the fabric has been fitted, attached, shrunk, taped and had its first coat of Poly Brush applied.

Then everything but the new fabric gets covered prior to the next coat of anti UV silver.

And it's only after all of these steps, on all of the fabric covered surfaces, that you can begin to apply the final colours. You had better be incredibly patient, persistent, skilled and have a desire for excellence to achieve these kinds of results.

Wings

- Cover port and starboard aileron assemblies with Poly Fibre fabric using STITS process up to silver.

- Sort, clean, repair aileron attach hardware as required.

- Test fit recovered ailerons to outer wing panels and check for rig. Remove same for final color scheme application.

- Formed port (red) and starboard (green) Plexiglas navigation light lenses.

- Installed after-market port and starboard wing tip navigation light assemblies (originals missing).

- Fabricated, attach hardware and installed port and starboard navigation light lenses in position.

- Applied green/brown Poly Fibre, Aero-Thane to various surfaces that will be enclosed/covered by panels and fairings.

Empennage

- Installed rudder trim tab and actuator assembly.

- Lock all turn barrels for rudder, elevators and trim tabs.

- Installed all tail fairings.

This fairing was in very poor condition having been walked on and folded in half. Only after many hours with a shaping hammer and beanbag could it be made suitable for installation. Amazing work by the crew at HASI, Greg and Buck.

Mosquito

Last month we received a package, courtesy again of our friend David Coeshall in England, with a variety of Mosquito parts. Three years ago we purchased a parts collection from Tony Bianchi when he was cleaning out his hangar. After David acquired and shipped the initial collection Tony discovered a few more odds and ends which David has been holding for us. Of particular interest was an exhaust pipe, of which we have none. One down, 23 to go...

In addition to the Bianchi parts, David was contacted by a friend who had a hydraulic valve that we just so happened to need. A deal was struck and it arrived with the other bits.

Our latest little treasure trove, courtesy of David Coeshall in England. The new hydraulic unit is at the lower left. Not very exciting to anyone but a Mossie nerd, but much needed. Additionally there are prop feathering buttons, a hydraulic piston, brake shoes, an access plate and our first exhaust stub.

Jack McWilliam

Here we go for Q1 of 2019 and how we stand for the first part of the year.

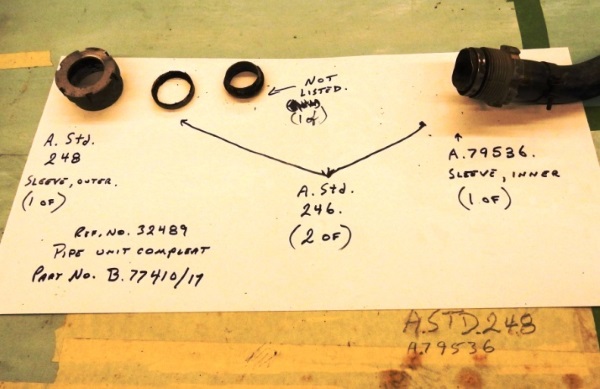

We continue to install new skins on the left side of the fuselage moving forward past the window positions. The skins are installed with the windows and Andy's ground power plug cut out.

Two new skins which encompass the porthole windows and the ground power plug.

Dick has started the next row of skins higher up the same side of the fuselage with the first sheet giving us the usual aggravation. This time it is the new plywood scarf joints not fitting as well as previous joints. We have also encountered some areas where the balsa is a little proud. Nothing that can't be overcome but the fine fitting process is very time consuming.

Roger and Peter have worked on the upper, exterior center line of the fuselage repairing plywood damage with layers of veneer then constructing a new strip of skin. We will be working on some final fit and finish issues before gluing the material on.

Peter and Roger working on the upper fuselage centerline joint and cover strip. This work will be complete by the time this report is published.

I am optimistic we should have the 2 mm skins finished for the aft fuselage before the end of April and then be able to move onto the 3 mm skins around the wing opening.

Right now I am hoping to clean up a lot of the various parts, with a different crew assigned to each area. The regular crew will each focus on just one spot as they deal with parts that have been cleaned and painted as well as trying to locate those that are either missing or misplaced. Of increasing value as we start to reinstall parts is the illustrated parts manual for proper assembly which has helpful pictures for comparison and installation.

All of the green painting boards hold dozens of small parts from which we can start building assemblies and then install the assemblies into the fuselage.

Andy has been installing the hardware around the armor plate in the cockpit with Davey's help as Dave had built the mockups holding the hardware. Communication is important in the assembly process as other people not directly involved can often contribute important pieces of the puzzle.

The rear side of bulkhead 2 where Andy W. is focused on reinstalling all of the hardware. On the front side of this bulkhead is the armour plate which protected the crew's lower legs, but also provided significant rigidity and strength to the forward fuselage area.

Brian is focused on cutting gaskets for components around the cockpit flooring so that both of the floor boards can be reinstalled together as more parts come off the mock ups that were created to hold parts as we completed structural repairs on the fuselage.

Don H. and Davey D. are both working on the tail wheel attach area as these parts are currently being painted prior to reinstallation. They should all be in place within the next few weeks.

Jack and Davey discuss what is required to complete bulkhead 7. Having finished structural repairs in this area we can now begin to reinstall all of the parts on this very critical component. Bulkhead 7 is the anchor point for the vertical stabilizer and rudder, the horizontal stabilizer and the tail wheel. Before installing all of the castings, brackets and hardware, we use a mockup to ensure that we have everything, know where it fits and how it all goes together.

Michael drew the short straw and got bulkhead 6 which is down at the skinny back end of the fuselage. Michael has been focused on the inside of the fuselage aft of the hell hole entrance hatch, cleaning off the last of the original paint under years of accumulated grime. Steve took a turn in this area as well to give Michael's back a break so we are left with one last try at removing the oil from the inside lower belly of the rear fuselage.

‘Short straw’ Michael down at the skinny end of the fuselage, working to clean up bulkhead 6. Don’t worry Michael; we’ll let you know before we turn out the lights and lock up at the end of the day...

We will be back with the cat litter and coffee grinder to remove what oil can be drawn out with these materials. We won't use solvents for fear of opening the wood grain and having the oil go deeper into the wood. Once we have cleaned out the ground up cat litter we will then clear coat the area. This should give us a better surface for paint adhesion. Painting will start shortly in the aft right side of the fuselage interior. The left side of the fuselage interior is on hold until the external skins are complete. We have learned that we need to seal the inside of the fuselage area as we apply new skins on the exterior with the vacuum process.

Inside the lower fuselage between bulkheads 5 and 6. The centerline strip has been removed and as can be seen, a lot of wood is stained and impregnated requiring us to clean as best as possible and then seal before painting. The area in red, as described below, presents a bit of a mystery as drawings and photos show this to be the attach point for a small platform. It was absent from our airplane and we are trying to figure if it was removed by Spartan or whether it was taken out and lost during earlier restoration efforts.

The copper grounding straps found throughout the fuselage interior have had a lot of attention as we work to clean, straighten, repair and as a last resort, replace some strips. Don Y. and Jeannot have scrubbed all the copper straps making them ready for repair or reinstallation. In addition to the straps we have removed for cleaning and repair, there are a number of sections missing and terminal ends with no straps, leaving us with more puzzles to solve.

We have also begun to address the issue of straightening existing pneumatic and hydraulic tubing. We have looked at some designs and materials for tubing straighteners while hoping that the plumbing will cooperate.

On the head scratching side, is an area in the aft fuselage behind bulkhead 5 with series of five holes and marks left from where a small wood shelf was once attached. Richard and Andy have researched the structure and equipment that had been mounted in this position (See photo above). What we do not know is whether its removal was done by Spartan as a modification or whether it was removed for another reason, perhaps as part of an early attempt at restoration.

As usual the aircraft continues to raise as many questions as we seem to answer. Our crew is in a constant state of flux, with some coming back from holidays and another leaving.

We were sad to lose one of our crew as he is leaving to return to Quebec. Jeannot has not been mentioned often in our reports but he has been a member of our crew for the winter months for a couple of years, diligently cleaning parts and getting them ready for painting; willingly taking up the tasks that many others hate doing. His quiet humor and solitary ways earned him our respect and a special place with the team.

Jeannot working on the copper grounding straps that criss cross the interior of the fuselage. After they were carefully removed they were mounted on boards so they could be paint stripped and polished. Our thanks to Jeannot for tackling this pain staking and often smelly job.

Events and Miscellaneous

CASINO.

On the weekend of January 19 and 20 we held our fundraising casino at Cash Casino Calgary. Thanks to board member Barry Davidson for herding all the cats and paperwork for this event and of course a big 'thank you' to all of the 'cats' and some of their family members for volunteering -especially those working the late, late shift. We should see the payout later in April and will report on it next quarter.

SPEAKING GIGS.

In February we had two speaking engagements which allowed us to continue to spread the gospel of the Mosquito and Hurricane and to fulfill our mandate to 'Honour and Educate'. The first was to an audience of 24 at the Calgary Gyro Club on February 6. The second was for a lunch time group of 42 for the Knights of the Round Table on February 19th.

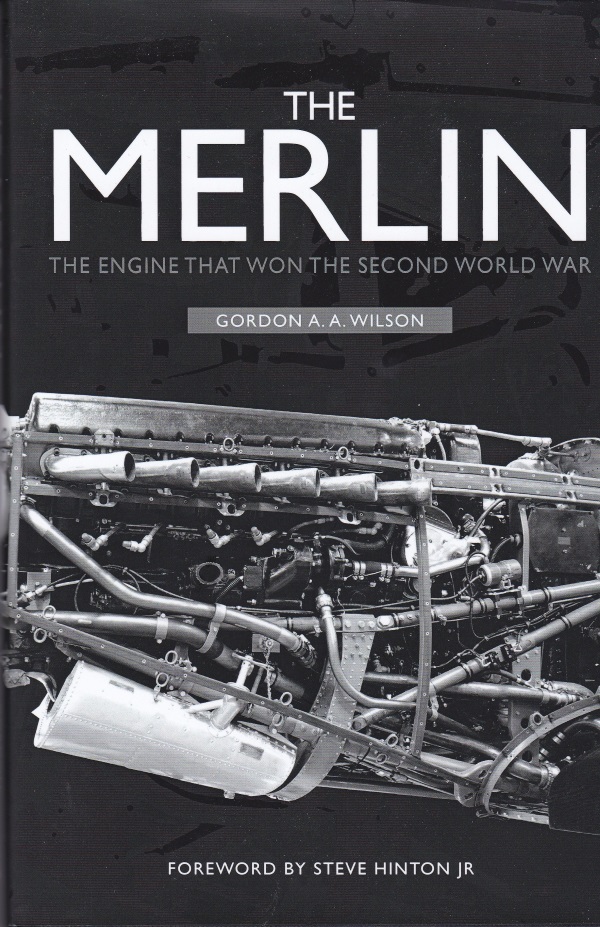

NEW BOOK.

We were pleased to see that our efforts are mentioned in a new book due for release on May 1, by Gordon A. A. Wilson about the legendary Merlin engine, which powered both of our aircraft as well as many more famous types of the era. Both our Hurricane Merlin 29 and Mosquito Merlin 113/114s are featured in the colour photo section of the book, along with our crew in the process of reinstalling the heads and banks on the Hurricane engine. Thanks also to Gordon for the advance copy of his new book.

ANNUAL GENERAL MEETING.

As is required by provincial regulation we held our AGM, this year on March 13. With interest building in anticipation of the Hurricane's completion we hosted a record number of members and interested parties at the Phoenix Education Foundation. Financial and membership reports were delivered and we got a briefing from VP Jack McWilliam on some restoration projects he learned about at the recent Mutual Concerns Conference in Tucson, AZ. There were no additions or deletions from our roster of board members for the coming year. We rounded out the event with an excellent (if I do say so myself) PowerPoint presentation highlighting the events and accomplishments of the society over the past year.

MEET AND GREET.

At the invitation and initiative of Jim Williams, Chairman of the Hangar Flight Museum, the board of the CMS attended a 'get to know you' event at the museum on March 27. With the impending completion of the Hurricane we will need to work with the museum on a number of issues and events concerning its arrival and Jim thought it would be a good idea if our groups met in advance and provided each other with a brief update after we had a chance to mingle, meet and munch.

HURRICANE INSPECTION.

On March 31 we conducted our quarterly inspection of the Hurricane at HASI in Wetaskiwin, in the company of Gordon M. Hill. As was mentioned, Gordon is the last surviving person to have flown Hurricane 5389 when it was operated by 133 Squadron of the RCAF during World War II. No doubt Gordon and his experiences will be a prominent feature of the Hurricane's arrival events in Calgary, but as he had not seen the airplane since 2013, and then only as a parts collection, we thought he might appreciate a look at it in one piece and before it becomes a public spectacle. It was an honour and a pleasure to be able to spend the day with Gordon, not just for me, but it was also remarked upon by the crew working on the airplane. It served as a good reminder to all of us that the airplane is a vessel by which we HONOUR and EDUCATE the service and sacrifice of so many. Thank you Gordon.

Gordon Hill is the last surviving man we know who flew Hurricane 5389 during the war. Gordon went on to fly 6 marks of Spitfire and was in combat with 416 Squadron of the RCAF from October 1944 to the end of the war. But it all started here with Gordon cutting his aerial combat teeth on Hurricane 5389 and her sister ships in 133 Squadron.

DONATION.

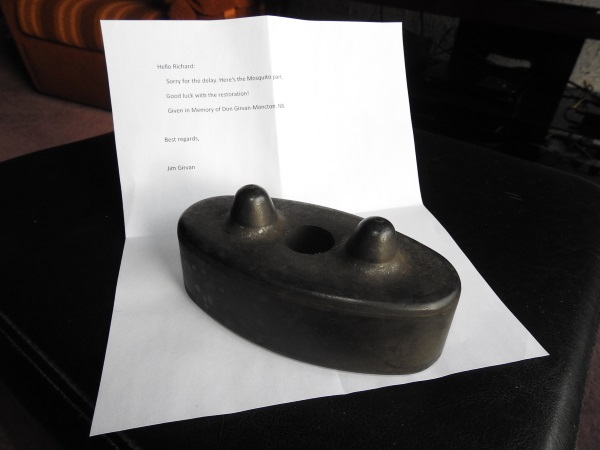

I sometimes think that if an airplane, especially such storied machines such as the Mosquito and Hurricane, had to carry the weight of all of the stories attached to them, that they never could have made it off the ground. We close this report with a note we received from Jim Girvan of Moncton, NB.

"Please forward to Mr. Richard de Boer:

I was listening to CBC's "As it Happens" for the Christmas Eve episode of "The Shepherd", when I heard your enthusiastic interview concerning your efforts to restore a static Mosquito aircraft and all the interesting history that went with it.

My father was an avid Mosquito fan and he used to wear a Mosquito tie-pin proudly to church on Sundays in the hopes of stirring up a conversation of all things WWII, especially aircraft. Being a young boy during WW2 in Moncton, NB (a major RCAF training center) was not easy for him to endure, what with all the various aircraft flying overhead all the time. Undoubtedly, this was the reason he was so enamored with aircraft and the war in general.

I worked for Coca-Cola in the mid- 1980's and was attempting to secure new business in Amherst, NS at Amherst EnHeat (enamel and heating, and formerly Canadian Car and Foundry Co.). A worker there knew my father's interest in Mosquitos and one day he asked me to follow him to the men's locker/change room where he opened his lunch pail and presented me with this black, rubbery part. He said, "Give this to your Dad". Asking what it was, he claimed it was a rubber bumper for the tail-end of a Mosquito fighter/bomber. I knew they had built the Anson there and done some assembly of Lancasters, but didn't know how he came to have this part-perhaps they made parts for the Mosquitos too. So, I gave the part to Dad, and he kept it all this time until his death in 2017.

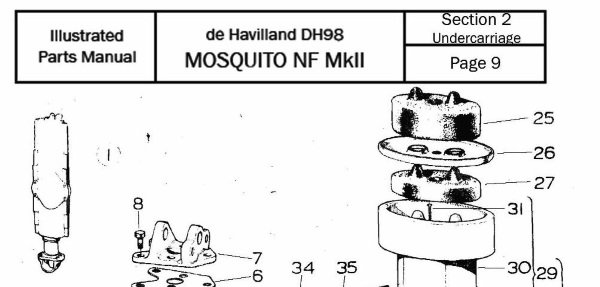

I believe the part has never been installed and is therefore NOS but shows some age of course. I'm not even sure it's from a Mosquito, but Dad thought it was correct, although not verified. Part # is G.9810 [Ed. It is of course a main undercarriage leg rubber compression block. Item 25 in the illustration below]. I thought that you might need the Mosquito bumper for your restoration, so I've attached a few pics for you to look at to verify the part for size, authenticity, etc. Just let me know what you think.

Regards,

Jim Girvan"

Thank you Jim. Item received and we will ensure its place in the restoration of our Mosquito in memory of your father Don Girvan.

Main undercarriage leg rubber compression block. Item 25 in the illustration.

Richard de Boer, President

April 13, 2019

Website - Calgary Mosquito Aircraft Society