Click on any image for a slideshow!

Spring Hurricanes and Pesky Mosquitoes!

Welcome to the salad days of 2023. Our Mossie volunteers were in great form over the past quarter, putting in more hours (1705 to be exact) than in any other quarter since 2016. Thank you gang. (Hope it is not just the donuts, chocolate and licorice that keep you coming out...). As stated before, restoring an airplane isn't a big job; it's five million little jobs. This report covers a whack and a half of those little jobs. Read on:

Hurricane

Just to backtrack a little, the plan is to get the Hurricane's Merlin 29 running before we drop it back into the airframe. In order to do that, we need an engine stand designed for running the engine and we need a test club propeller.

When we pulled the engine from the airplane we had a stand designed by board member Andy W. that was intended for the job of overhauling the engine, but it was not designed to run the engine because that was not the plan at the time. We talked to our hosts at the Bomber Command Museum about splitting the cost on an engine stand and trailer because they were overhauling a spare Merlin for their Lancaster and they intend to ground run it on a regular basis. They went to their friends at Falcan Industries in Ft. Macleod about building such a unit with the idea that we would split the cost with them. Long story short, the estimated cost is very high and for our one time use, it makes little sense for us to cover half the cost. The other issue is that Falcan is busy and likely can't get at it for months to come. That brings us back to redesigning our overhaul stand so that it can be used for running the engine. For that we need it higher, wider and with fuel, oil, radiator, controls and instruments.

We've been on the hunt for a club prop for some months and are grateful to the Hangar Flight Museum for allowing us access to their storage trailers and sheds in which we found a good selection of prop hubs and blades, some of which are damaged, making them suitable for being cut down. We then talked to three propeller shops in Winnipeg and Vancouver and we now have a good lead on an existing club prop that may be available. Failing that, we have a very reasonable quote on having one built for us from the parts acquired at the Hangar. Fingers crossed.

While this has been going on, and while our key volunteers have been catching up on post-covid world travels, we are back to the final tasks on the engine itself, namely timing valves and magnetos. Hope to have that done within a couple of weeks.

A lot of aeronautical brain power and experience at work here on the Hurricane’s Merlin 29. Jack M., Brian T. (on loan from the Bomber Command Museum), Davy D. and Dick S. working to get the gap right twixt valves and cams.

Mosquito

Speaking of the Hangar Flight Museum, our snooping through their storage areas has rendered some fantastic finds for the Mosquito as well, namely a long lost hydraulic reservoir and a section of the instrument panel. Andy W. with assistance and support from the Hangar's Brian Desjardin and Herb Grieder has spent some very dusty and fruitful hours digging through dark and dank overloaded shelves to unearth these treasures. Thank you gents!

Above is the far right side of the Mosquito's instrument and control panel discovered at the Hangar Flight Museum. Below, Don H. displays the long missing and now recovered hydraulic reservoir, also found at the museum. What makes this one a head scratcher is that we have pictures of it with the Mosquito in the city warehouse just prior to our moving the airplane.

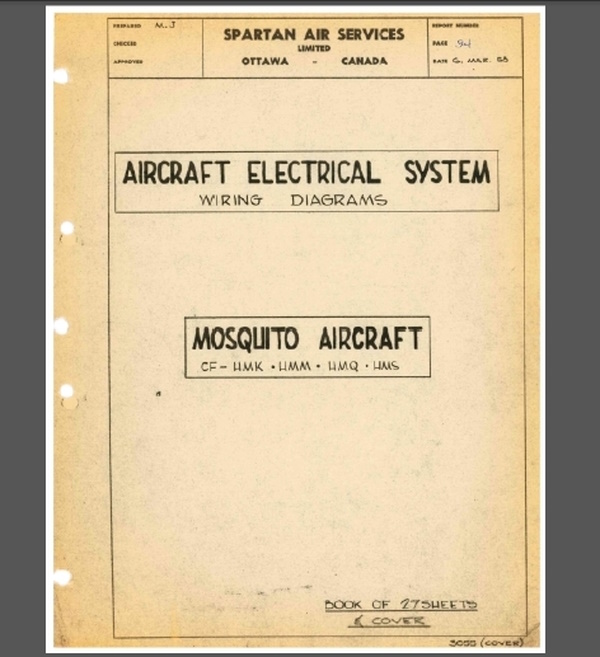

We continue a mutually beneficial trade relationship with the good folks at KF Aero in Kelowna, the operators of flying Mosquito C-FHMJ. We loaned them an aileron center hinge and were rewarded first with a digital and then with the original paper copy of a Spartan Air Services Electrical System Wiring Manual. Big thanks to KF's D'Arcy Barker. We then sent KF a tail wheel retract jack so that they could reverse engineer a fitting for Mosquito KA114, owned and operated by the Military Aviation Museum in Virginia Beach, VA., while at the same time making extras for themselves and for us.

An aileron hinge above, which we sent to KF Aero and the original Spartan manual on Electrical Systems which we received from them. Quid pro quo at its best.

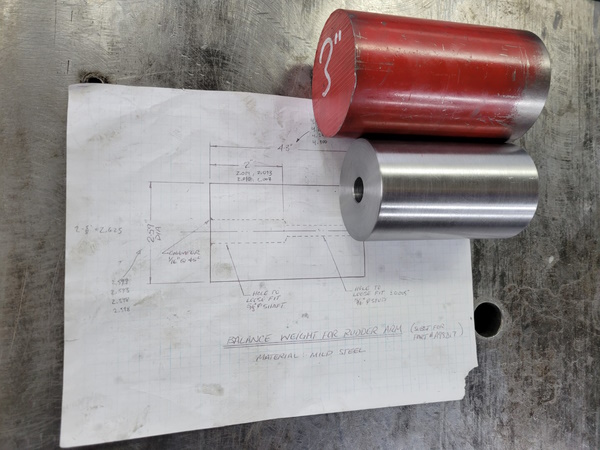

Many full moons ago, our volunteer Steve S. undertook to machine us a new rudder counterbalance weight. As Steve finished off the little home project, he was tickled to note that his Clausing 12" Model 100 Series Mk. 3a metal lathe, on which he turned the weight, was manufactured in the same year as our airplane: 1946.

Our shiny new rudder balance counterweight above and below, Steve S. (right) with friend and neighbour Josh and the 1946 Clausing metal lathe on which he made it. Photos Steve S.

Shout out as well to John Weatherseed, Managing Director of The Vintage Aviation Team out of Cheltenham, ON. This outfit acquired boxes of old Spartan Air Services records and documents and on his recent trip 'out west' John hauled the boxes with him so that we could rifle through them looking for any Mossie specific documents that may assist in our restoration efforts. Board members Jack M., Andy W. and Colette P. met John in Nanton to show him our project and to sort through his cardboard treasure chest. John agreed to take home and scan all the documents we identified as useful to our efforts. Thank you John and TVAT.

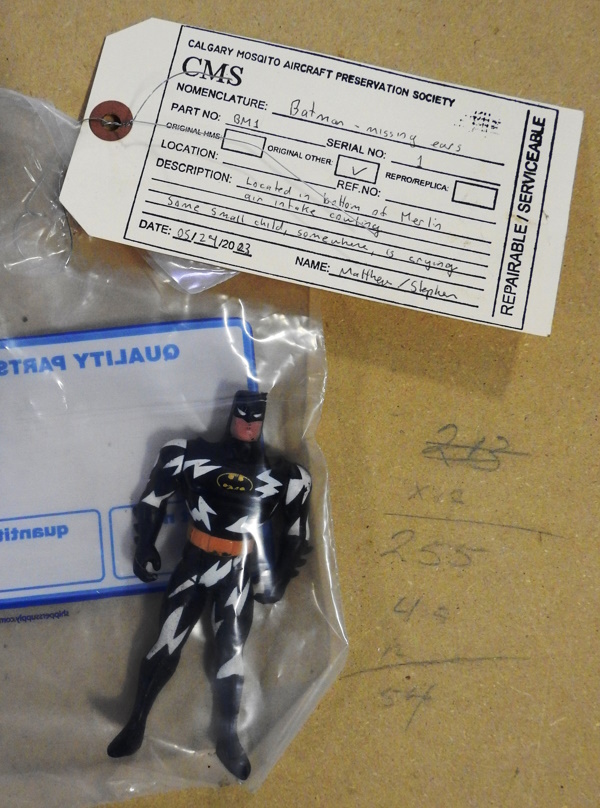

The Mosquito's two Merlin engines have been on rolling stands as complete units since they arrived in Calgary in 1965. Our friends at the Windsor Mosquito Group had questions about a pump and how it mounted at the bottom of the engine. In order to find out, we put volunteers Matthew and dad Steve S. to work, along with Brian C. pulling the cowlings and filters from one of our engines in order to answer the question for Windsor and to provide them with some photos of said pump.

Steve S., Brian C., supervising Matthew S. as he removed the cowlings from one of our engines so as to get at a pump for Windsor. In the process, Matthew found the figure at right, at the bottom of the engine. Note that Matthew had properly bagged, tagged and assigned a part number to it. Contact CMS to claim if yours...

Jack McWilliam

No big changes; this report is all about a bunch of little details making progress toward the big picture.

I am not sure how you describe retirees taking trips. Is that a vacation or just a day like any other? (Wink, wink. Nudge, nudge). Now that we are clear of covid restrictions, lots of our volunteers have been catching up on their much delayed travel plans. A lot of the guys have been off roaming the planet so progress has slowed and even stopped in some areas during this quarter.

We will start with the landing gear which has gotten a lot of attention over the past few months. Thankfully we have enough experience to know not to disassemble both units at the same time, leaving one intact as an example for how to put the first one back together. Jaimie G. is the first one on the list as he is focused on getting the first main landing gear back together. Sadly, as in this case, most aircraft manuals just say 'reverse disassembly procedure', which provides little of value and serves to do little more than annoy most aircraft engineers. Thankfully Jaimie did an outstanding job of documenting the disassembly.

With Don H. having returned most of the undercarriage parts from the paint shop, Jaimie has now started getting things in order prior to reassembly. The first component to attend to is a large cross member with bearings inside that use a type of grease not unlike roof tar. To separate the components we had to remove four large untapered rivets by grinding the heads off and knocking them out. To facilitate putting this component back together, while maintaining a way to disassemble it again, I have elected to build special shouldered bolts for it rather than go back to semi-permanent rivets. For this we will take advantage of Gary T's, lathe and machining skills to modify some larger bolts and curved washers. Basically we need a dash 6 turned into a 5.5 and a dash7 turned into to a 6.5, which should give us a perfect fit.

The firewall, to which the main undercarriage cross tubes are attached, has received a lot of attention from Davy D. over the past few months as he stripped it clean, transferring all the parts to a mock up board. It then went to Dick S. for some minor repairs and re-riveting before coming to me for a new coat of primer and paint.

But before I could do my prime and paint thing, I sent the firewall and related parts off to Richard, Cam B. and Alan W., the latter two of whom have also been off roaming the world this quarter. These guys do the detailing in the form of masking and mounting for painting as well as wiping away all the fingerprints. The firewall will then go to Mathew

Dick S. does some remedial riveting on the firewall prior to it being masked and painted. Many, many hours have gone into stripping this of dozens of parts and lines. Thx Davy D.!

and Andrew S. for the actual painting. This group has been traveling down this road for a while, having already handled a number of other components such as rudder pedal parts, instrument panel mounts, fuel system parts and electrical boxes.

Happy volunteers Andrew S. and Davy D. engaged in the seemingly endless job of taking stuff apart and prepping it for painting.

Andy W. has been hard at work on a number of projects in the cockpit. He now has the starboard side junction and fuel panel boxes stripped down and has passed them on to our paint crew. These boxes have been a major pain for me as our black paint has not adhered as intended. We are using the same type of paint as we have used for our silver and green colours, but we've had a variety of problems with the black. After a number of tries I think the problem is in the gun which appears to improve by turning the air pressure down to minimum. I will know in the next few days as I have the parts sanded and ready to go. This is just one example of how we run into challenges when our expectation is that it should be a breeze.

Also I want to give a shout to the Herb and Brian of the Hangar Flight Museum, as they have given us access to their storage trailers and sheds which have yielded some important finds for us. We are crating and cataloguing some of the items that we will be returning to them and hope that this assists their storage issues as well.

Don H. continues to make progress in the rear fuselage by installing the camera magazine shelf and starting to look at hydraulic and pneumatic lines along with the block clamps that hold all this al dente aluminum tubing in place.

Andy W. is our cockpit specialist and here he shows off some of his handiwork in bringing the engine panel up to authentic Spartan standards and in the cockpit below, he is dry fitting some of the components and supports that will eventually make up the complete and authentic set of instrument panels and controls.

Nigel C. and Davy D. work together to remove some very corroded and stubborn bits of metal from the forward spar of the wing. (The wing is mounted vertically, leading edge down). All of our crew look forward to seeing this work completed so as not to have to listen to the 'Noise!' warning before the air gun is employed to knock out a recalcitrant bolt.

Michael H., Nigel C. and Jerry M., are still busy on the underside of the wing, removing some very stubborn steel parts and continuing to clean up the fuel and undercarriage bays. Some of the through bolts that have been sitting in the wood structure for decades have corroded beyond any hope of reuse and we will have to look at replacing or remanufacturing some of them. In one case they needed to disassemble some of the wing structure in order to remove some of the steel bits. We also found some of the attaching hardware to be simple threaded rod rather than bolts. We will look at sealing some of the wood before replacing the steel parts to cut down on future corrosion issues.

Our wing crew has also found that the wheel wells are saturated with oil and grease so we are looking at how to repaint the plywood structure in these areas. Two part epoxy paints are no longer available so we have tried a replacement product recommended by our paint shop, to see how it adheres and seals. If it works, we will use it as a primer for the bays and underside of the wing.

With Gary T. back from his European wanderings he is now dealing with repairing, and in some areas replacing, the rear spar cap or shear web. This strip is comprised of plywood of three different thicknesses of 3, 4 and 5 mm. As we do not have any 4 mm, we may sand down an 18 inch section of 5 mm if necessary.

Events and Miscellaneous

As we are now a year clear of covid restrictions, life is returning, with some exceptions, to its previous rhythms. The Bomber Command Museum held its annual Air Cadet/Clean Up weekend in mid April, which included our spending some quality Mosquito time with the gang before they enjoyed a Lanc engine run.

The Air Cadet squadrons from the Crowsnest Pass area came out for their annual sleepover weekend at the Bomber Command Museum at which they help with some spring cleaning and spent time with museum and project leaders learning about aeronautics and the history of specific aircraft.

On May 18th the museum held their 80th Anniversary of the Dambusters Raid event, which among other things, featured yours truly delivering the afternoon talk on the history of 617 Squadron to an audience of over 200 attendees.

Despite an afternoon shower that served to clean the Lanc, the turnout was good and we spent the day talking to visitors about restoration progress on the Mosquito.

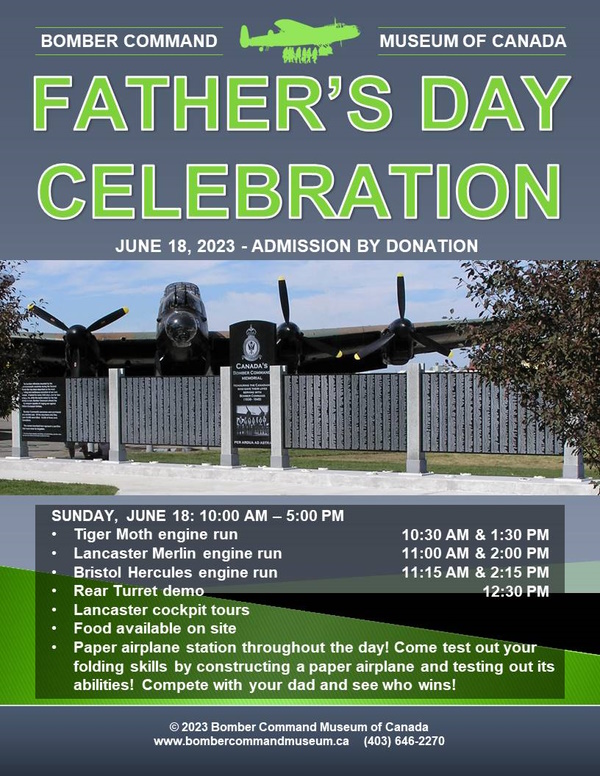

We also gave tours and provided restoration updates to a good turnout of visitors for the June 18th Father's Day event at Bomber Command Museum, which as usual featured a variety of outdoor engine run ups in the morning and afternoon.

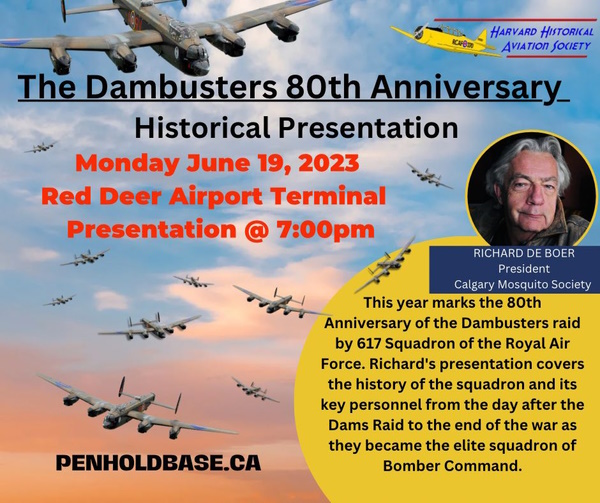

The Dambusters talk was well received and as a result we were invited to deliver it to a joint meeting of the Harvard Historical Society and the Red Deer Flying Club on June 19.

Richard de Boer, President

July 10, 2023

Website - Calgary Mosquito Aircraft Society