Q2; What Did We Do?

Back in April we posted a report detailing what we had been up to in the first quarter of the year. That story was based on a report that we have to file with the City of Calgary every quarter of the year. Having received all manner of positive feedback, here is the report on our activities for the second quarter of this year.

Volunteer Hours

We almost matched the record number of volunteer hours for the first quarter of this year. The total for the second quarter of the year, April through June, came to 1465.5 hours (1514.5 for the first quarter of the year). That breaks down into 122 hours of admin work by board members, 287.5 on the Hurricane engine and 1056.0 on the Mosquito.

It's important to keep track of our time for a number of reasons, not the least of which is that the City credits us $15 for every volunteer hour. That makes our time in the past three months worth about $22,000.

Fundraising

A few donations this quarter along with membership renewals, amounting to just a few hundred dollars. We continue to recruit and coordinate volunteers for our late August 27 and 28 casino.

Hurricane

The focus during the past quarter continues on the restoration of the fuselage and center section. As of the end of this quarter Historic Aviation Services Inc. (HASI) estimates that they are at the 35% completion mark on Phase 4 of the project, with completion of the entire project by May 2017. We conducted our onsite inspection for this quarter on May 30th.

As was discussed in our last report, the issue of missing pieces gets ever more critical as the restoration progresses. Often work on a section has to be halted until Hurricane specific parts can be located.

We contacted Hawker Restorations of Suffolk, England recognizing that with ten Hurricane restorations since 1993 to their credit, that they are world leaders in the type and the most likely source of critical parts for our project. (Check out their very cool site: hawkerrestorations.co.uk) After an encouraging initial exchange with company owner Tony Ditheridge, he suggested that it would be best if we could supply them with a comprehensive 'want list' rather than inquiring about individual pieces as we discover the need.

With that in mind, HASI has redirected their efforts of late to do a general layout of the parts on hand along with completing a comprehensive inventory in order to assemble a 'shopping list' that we can compile for Hawker Restorations. We anticipate being able to send them a fairly complete list by the end of July.

As well, HASI has established a relationship with the restoration crew working on a Hurricane for Vintage Wings in Gatineau, PQ. They have offered to help with some missing parts. HASI will send a representative out before the end of July.

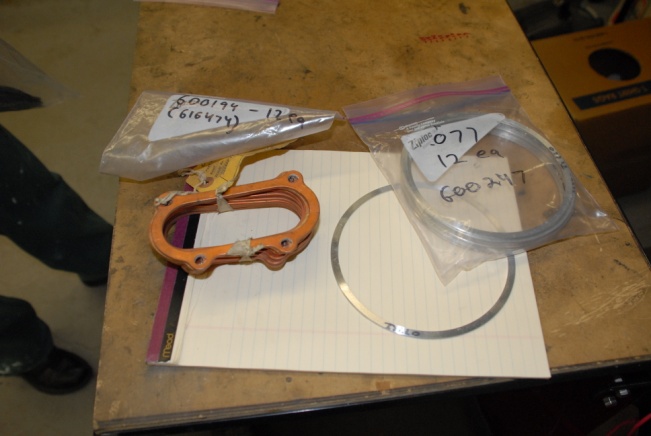

Guns

This Hurricane, being a Canadian built Mk. XIIB, sported six .303 Browning machine guns in each wing. During WWII the guns were made in large numbers in Canada by Inglis, the washing machine company. CMS member Jeff C. who is an active gun collector, has begun to source these for us. Though both wood and metal replicas are available, it was decided by the board that our first choice was to use original weapons that have been rendered inoperative. Last month we acquired our first from a collector in Ontario. Should we be unable to acquire twelve original pieces we will resort to metal replicas to complete the gun bays.

Our first Mk.II, .303 Inglis/Browning machine gun for the Hurricane.

Centre Section

- Port and starboard centre section trailing edge (CSTE) assemblies cleaned and inspected for required repairs.

- Both assemblies dismantled as required including removal of upper and lower skins and inner flap compartment rear spar cap panels.

- Completed required repairs to CSTE primary built up rib structures. Both assemblies primed, butyrate doped and attached to centre section.

Port side center section trailing edge prior to restoration.

- Fabricated new CSTE top skins using damaged originals as patterns. Primed, butyrate doped same and installed on respective built up rib structures.

- Repaired port and starboard upper and lower rear spar cap panels as required and reinstalled on CSTE assemblies.

- Fabricated new port wood flap bay fairing using original as pattern. Installed same on CSTE.

- Repaired starboard wood flap bay fairing as required. Installed same on CSTE.

- CSTE walkway assembly and support structure cleaned, inspected, repaired as required, primed, butyrate doped and reinstalled.

- Centre section flap assembly cleaned and inspected and disassembled as required.

- Centre section flap spar hinges and couplers found completely seized, serviced same and reinstalled on flap assembly.

- Centre section flap flex panels found completely seized - serviced same, made up one new torsion hinge and reinstalled both flex panels on centre section flap assembly.

- Centre section flap assembly completely reassembled, primed and butyrate doped.

- Flap assembly fitted to rear of centre section and rigged.

Center section flap cleaned, freshly primed and finished in butyrate dope.

Fuselage

- Firewall assembly cleaned and inspected.

Cockpit to engine firewall repairs in progress.

- Firewall assembly repairs (corrosion, dents, scratches, missing insulation) underway.

- Cowling panels removed from motor mount assembly. Cowling repairs underway.

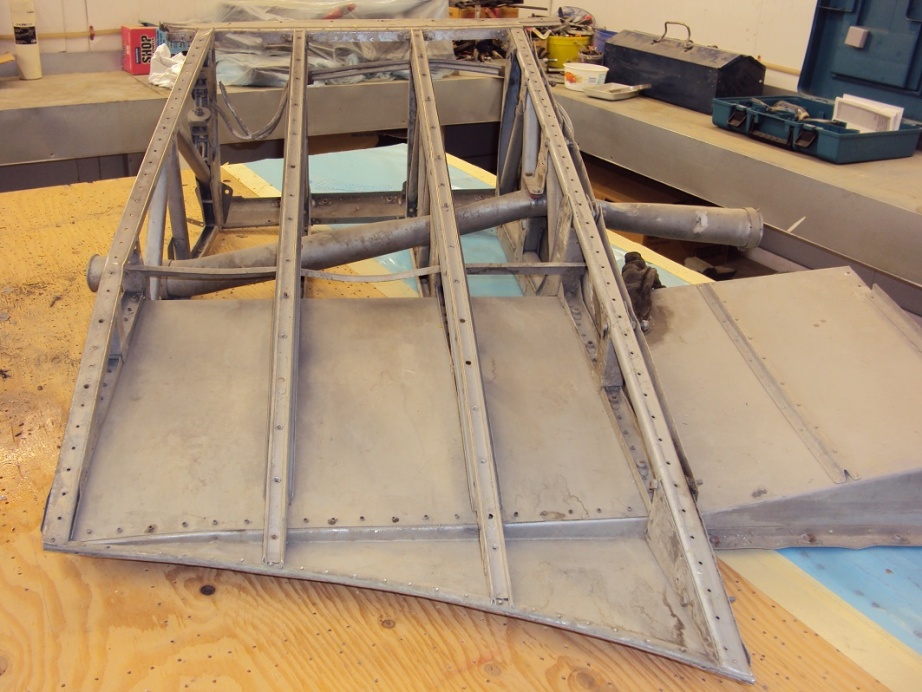

- Motor mount assembly trial fitted to fuselage.

Coming together: The engine truss is trial fitted to the fuselage and center section.

Hurricane Engine

This quarter has seen some significant progress and milestones in the restoration of the Hurricane's Merlin 29 engine. After many months, the kit of gaskets and seals finally arrived from Vintage V-12s, as did the coolant pump, which was sent for overhaul on the advice of Bomber Command Museum engineers.

New seals and gaskets from Vintage V'12s of Tehachapie, CA. Nice to be able to buy new parts off the shelf for a 73 year old engine.

While awaiting the arrival of these items, it was decided that we could spruce up the engine itself by painting the heads and banks which had been removed for inspection and gasket replacement. Doing so required many hours of taping and masking prior to priming and painting them.

CMS volunteers, Bev, Bert, Roberto, Andy, Cam, Paul and Brian mask and tape the Hurricane Merlin 29 heads and banks in preparation for priming and painting.

The results turned out to be a bit of a double edged sword in that they looked so good it was decided that we should refinish the whole engine. This will be a very labour intensive undertaking, but was a decision that was easily and readily agreed upon by those involved. Critics have suggested that it is unnecessary to do so as the engine will be enclosed within its cowlings and therefore rarely if ever seen. While true, our standard is defined by the fact that we will know what was done and by our desire to do the best job possible even if it is not seen by others. Doing so will entail a great deal of work but will not delay the project overall.

CMS's youngest volunteer Jordan admires some of his handiwork on the newly primed and painted Merlin engine cylinder banks.

Polished and honed cylinders and brass coolant tubes contrast with the newly painted finish on the engine banks

Mosquito

We have turned a very important corner in the restoration of the Mosquito. After almost three years of sorting parts, building work benches and storage crates, identifying parts, sourcing materials, cleaning and stripping parts and building fixtures, the majority of our time and energy has now finally shifted into actual restoration on the Mosquito, much to the relief of many volunteers. Structural repairs on the fuselage are the first key areas to receive attention. All of the work to date, often tedious and repetitive, was necessary in order to create a clear and strong foundation from which to start the actual work on the airplane.

In addition to our Tuesday evening and Saturday work days, a number of people and projects are on the go throughout the week. CMS member Rick F. has undertaken the job of sourcing from around the world all the cockpit fittings and instrument panels for the airplane.

Newly sourced and restored instruments. A weekday project by Rick F. who continues to source instruments and cockpit controls from eastern Canada, Australia and England.

Retired engineer Dick S. is creating jigs and manufacturing new wood stringers and ribs for the Mosquito fuselage. These are tested and fitted on Saturdays prior to installation. As well, he and Don Y. are our weekday gophers and fetchers for tools, materials and third party work such as welding on the wing and fuselage fixtures.

At the initiative of J.P. Brescacin of the Windsor (Ontario) Mosquito Group, we have begun to build a network of the people and organizations active on the restoration and operation Mosquitoes. We have to date had contact with numerous groups, individuals and museums on an ad hoc basis. Our efforts now are intended to build a Mosquito 'Net'work of those who are active on the type so as to share resources, parts, vendors, and experience. The group will likely not include museums which simply display a static Mosquito and who are not actively restoring their airplane. The thinking is to include just two or three key members of each group who are knowledgeable and active on the restoration side of these projects. Its early days, but we are encourage by the positive response from most of the people we have contacted. It is understandable as well that some wish to hold their cards close to their chest, but the potential benefit to all concerned is the ultimate goal of this effort.

Our thanks go out to Vancouver Mosquito owner Bob Jens and his engineer Mel Johnston for lending us a pair of exhaust stubs. Our project is missing the full set of 24. Our thinking is to get a 3D scan of these pipes and if necessary get Acorn Welding of Edmonton to manufacture a set for us.

Jack McWilliam

April saw the completion of the new wing fixture after waiting for the arrival of the 3" square tubing that was three weeks delayed. Upon completion, the wing was lifted into the new fixture to provide more vertical clearance, as well as greater stability and mobility.

The recently arrived plywood from Austria had to be stored before the wing could be installed in the fixture. The wood provided a slightly different problem: It is metric in not only thickness but dimension at 5' x 10.5' so normal shelving wasn't an option. Pallet racking was determined to be the best option being that it was available in 12' lengths. The Target stores liquidation became an option but after waiting a number of weeks for a firm commitment Waymarc Industries provided us with new racking for the same price quoted to us by Target.

The Mosquito wing in its new fixture, now more secure, stable and portable than before.

Once the wing was moved back to position the fuselage work was restarted. A jig was constructed to cut out the damaged areas of the cockpit floor. A pattern cutter was machined for the work and the damaged areas on the port side floor have been cut out and repaired. The original ribs have been cleaned for the cockpit and are ready to be re 'glued in the floor. Most of the anchor nuts have been cleaned and tapped for reuse.

Using a purpose built pattern cutter, Wayne removes damaged areas of the cockpit floor.

The rear fuselage continues to be cleaned of debris and oils with still more on the go.

CMS Treasurer Colette P. has invested many hours in the 'glamorous' work of cleaning and scraping the interior of the rear fuselage.

The over wing area of the fuselage is our main focus at this point, as this area is both the most damaged and the most vulnerable. We are in possession of some, but by no means all of blueprints for this area, which makes repairs in this delicate area more challenging. As per the manuals, the fuselage from behind the cockpit to bulkhead three is an area with very little tolerance for repair. Regardless, we are working toward rebuilding most of it. The area was heavily damaged both from exposure when the airplane was stored outdoors and from crude previous repairs.

David D. working on the fuselage upper port side: Badly damaged, poorly repaired and critical to the structure of the airplane.

The top of the fuselage is to have a hole in the position from bulkhead 2.5 to bulkhead 3 for the dingy box, or for Spartan Mosquitoes, an antenna mounted to a hinged panel. We are now in possession of both a dingy box and the Spartan antenna and panel. At some time in the past this area was very crudely covered over with cedar strips.

We have focused on the port side of the over wing fuselage as our first area to repair. To facilitate these repairs, we built two moveable scaffold sections. The materials have been removed to expose the inner skin which, quite literally has hundreds of staple holes, well as missing material which was pulled out with components. A repair method has been agreed upon and we have identified the area to be cut out and replaced with new material.

Some of the stringers are cut and ready for installation. We have also begun to repair the areas around the antenna mount. Newly manufactured ribs are being constructed through the week, with the final fit done on the aircraft on Saturdays. These ribs consist of thin layers of veneer curved into shape in a mold, glued, planed and cut into position. A large number of veneer strips have been cut to build the required ribs which all seem to be of different sizes (couldn't make it easy).

The inner skin will be joined to the old skin with an internal lap joint, which will give us the strength with the repair facing inward and not be visible once the balsa has been installed. The original skin joints will not be touched both to preserve the original structure and limit the work on the primary structure.

An interesting side note is the fact that an area of primary structure thought to be spruce turned out to be plywood. The right side has an area of about 4' of dry rot to deal with on a compound curve but that will be dealt with in the coming weeks.

The mechanical components for the bulkhead are in Calgary being restored through the week for refitting once the structure is repaired. These components consist of connectors, fittings and valves which are being cleaned, inspected and repainted as required. Experiments continue on the most efficient method to clean the tiny screws holding the connectors together as they are made of both brass and steel.

Wood screws are being sourced through marine suppliers in Victoria, B.C., who in turn buys them from a supplier in the U.K. The aircraft suppliers have a very limited size range and quantity. This can present challenges as for example, the first stringer that we reproduced is just 2' long, but the blueprint calls for 19 screws to attach it to the skin. The screws are one inch long, #4 screws. The longest available in that diameter is made of brass.

The method of installation for the screws will be to tap the hole with a steel screw then replace it with a brass screw. Our only other area of concern is that the screws are now made with Robertson, rather than slotted heads. That said the newly installed screws will be distinguished from the originals by this feature.

Working from the newly constructed scaffold, Brian and Andy tackle some of the delicate repairs on the port side upper fuselage.

Displays and Presentations

As always we continue to participate in the open house and special event days organized by our hosts at the Bomber Command Museum in Nanton. In this past quarter that included their season kickoff event on April 25, their Expansion Gala Fund Raiser on May 9 and the big Nanton Celebrates History event on June 6. At all of these events we staff our permanent display and in truth, on these days, our restoration crew spends more time talking to visitors than working on the Mosquito. But that too is part of our mandate.

Working on the Mosquito during a special event day at the Bomber Command Museum and staffing our permanent display, chatting with visitors and selling pins, prints and memberships

As Historic Aviation Services operates as a closed shop, we arranged again this year to do a special visit so that members of the CMS could get a firsthand look at the restoration progress on the Hurricane and to get a behind the scenes look at the Reynolds Alberta Museum. This year's tour took place on May 30 and was again a tremendous success with members very impressed by the work on the Hurricane and thrilled to get a look into the normally inaccessible storage areas of the provincial transportation museum.

Byron Reynolds explains to members of the CMS what work needs to be done on the Hurricane's horizontal stabilizer during our tour of HASI on May 30.

Miscellaneous and In the Work

The CMS is actively working with the Calgary Foundation through their Community Knowledge Center to develop an online resource that informs and connects citizens, donors, and media to the needs in our community and the opportunities to make a meaningful contribution. After the City of Calgary, the Calgary Foundation is the largest cash donor supporting the restoration of the Mosquito and Hurricane. You can visit the Community Knowledge Center at: ckc.calgaryfoundation.org

In late June we received five more 'fine' cut videos from Pan Productions as well as the first rough cuts of ten more videos. We are very pleased with the video production work they are doing to assist the CMS in fulfilling their mandate to 'Honour' and 'Educate'. When complete, thirty short videos will be available to visitors on touchscreen monitors adjacent to the aircraft, on our YouTube channel and for sale on DVD. All thirty videos will be complete and available before the end of the year.

Richard de Boer, President

July 12, 2015